Top 5 Electric Bike Repair Mistakes Riders Make (And How to Avoid Them)

Introduction

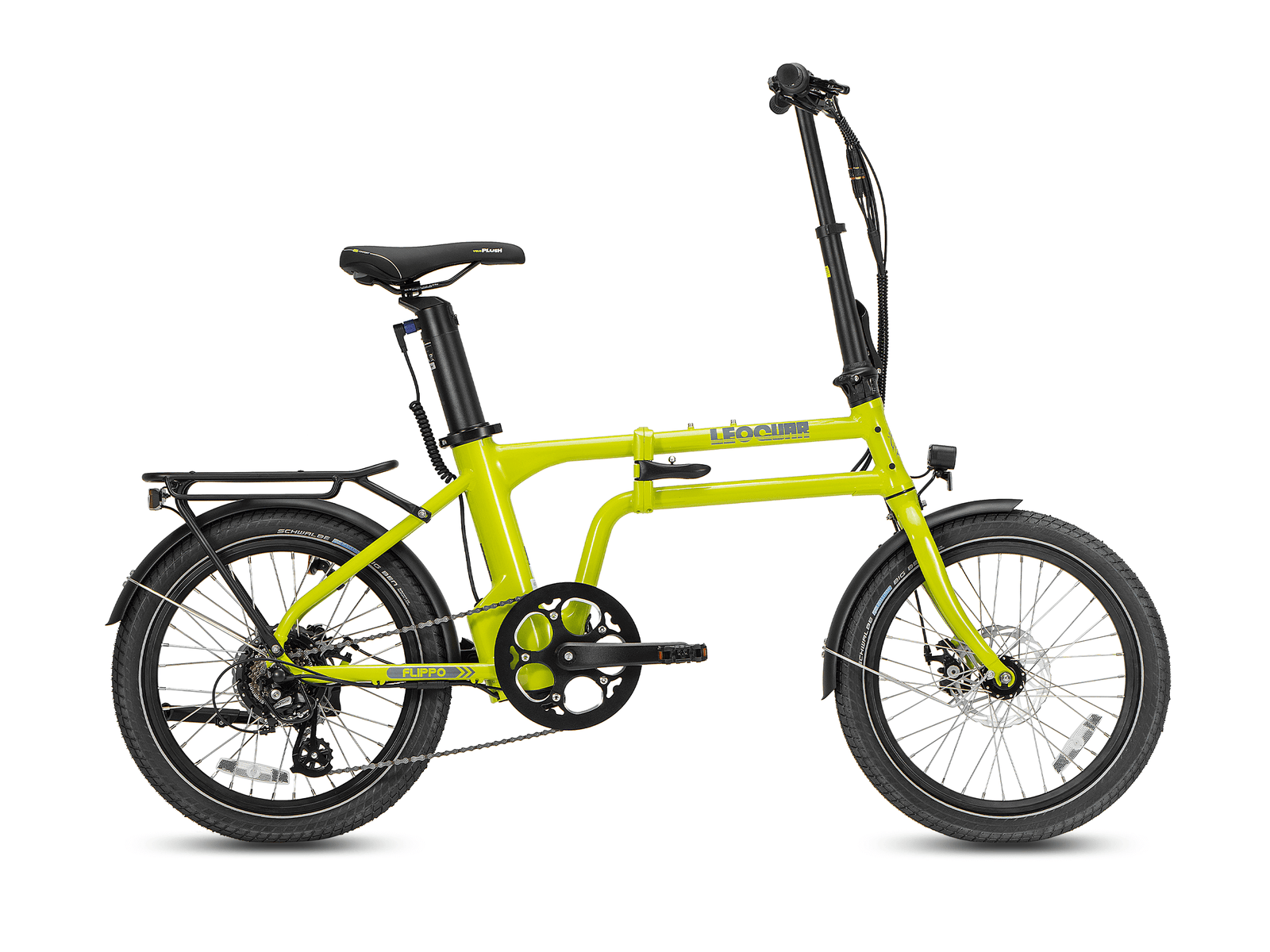

Electric bikes have surged in popularity as a sustainable, efficient mode of transportation. Maintenance and proper electric bike repair are fundamental not only for optimal performance but also for safety and longevity.

Riders of all experience levels face repair challenges. Routine maintenance combined with early detection of faults can make the difference between a smooth ride and unforeseen breakdowns. Top 5 Electric Bike Repair Mistakes Riders Make (And How to Avoid Them) is designed to provide actionable tips backed by first-hand industry insights.

While many enthusiasts tackle repairs on their own, even minor errors can evolve into serious issues over time. Using proper tools and following the right technical guidelines is essential to avoid further damage. For example, using a torque wrench properly prevents over-tightening or under-tightening bolts, which is a recurring issue among many riders.

It is vital to address common mistakes such as incorrect fastening, poor battery maintenance, wiring issues, harsh cleaning techniques, and overlooked brake and drivetrain servicing. Each mistake not only impacts the performance of your e-bike but can also compromise safety on every ride. Detailed troubleshooting steps empower riders to tackle these issues confidently.

We have drawn on decades of collective experience in electric bike repair and maintenance. For further background on maintenance best practices, see REI Expert Advice on Electric Bike Maintenance.

By understanding these common pitfalls, riders can extend the life of their electric bikes while avoiding unnecessary repair expenses. Our guide outlines each mistake in depth, with specific technical recommendations and checklists that have proven effective in real-world repair scenarios. In the following sections, practical tools, recommended techniques, and data-backed advice will be provided.

Clear, concise instructions and real examples from experienced mechanics ensure that even beginners will feel confident in performing their own electric bike repair. We have intentionally kept our language professional yet friendly, so that every rider feels supported in maintaining their bike's performance and reliability.

Mistake #1: Improper Fastening – Under-Tightening or Over-Tightening Bolts

Incorrect bolt fastening compromises the integrity of numerous components on an electric bike. Too often, riders either under-tighten bolts, leaving components loose and vulnerable, or over-tighten them, damaging threads and causing premature wear.

In many workshop scenarios, a mismatch in tool calibration results in failure to adhere to manufacturer-recommended torque settings. A common instance involves saddle and handlebar bolt adjustments where slight miscalibration can lead to loosening during a ride. This mistake may seem trivial but has far-reaching impacts on both safety and performance.

Using a calibrated torque wrench is essential when performing any bolt adjustments on your e-bike. We advise consulting the manufacturer's manual for exact torque values, as these values can vary based on model and component. Professional mechanics detail how even minor deviations in torque can lead to strip threads and cause irreversible damage.

Several experienced repairers observe that under-tightened bolts lead to subtle vibrations that gradually wear out other components, such as the frame joints and connectors. Conversely, over-tightening can crack plastic inserts and damage aluminum frames. These issues gradually compound, resulting in costly repairs that could have been prevented with proper fastening techniques.

A step-by-step matching process is recommended: begin by cleaning bolt interfaces and then applying the right lubricant if the manufacturer advises it. Gradually tighten the bolts using incremental turns while periodically re-checking the torque settings. We recommend a cross-pattern tightening technique to distribute pressure equally across the component.

A practical tip from the frontline workshops is to always have spare bolts and check for any signs of wear on the threads before beginning repairs. Once a bolt shows signs of stripped threads or corrosion, it should be replaced immediately to maintain optimal performance and rider safety.

Additionally, investing in quality tools such as digital torque wrenches ensures accuracy. Some repair stations even use torque calibration tools that provide audible clicks to inform the technician of the proper setting. Such practices significantly reduce repair errors and enhance overall bike reliability.

A table below summarizes the best practices for bolt fastening:

| Tip | Do's | Don'ts |

| Clean Bolt Interfaces | Wipe off debris and residue before tightening. | Neglect cleaning before application. |

| Use Torque Wrench | Set to manufacturer's specifications; verify accuracy. | Rely on thumb-tightening techniques. |

| Lubricate if Advised | Use recommended lubricants to ease the tightening process. | Use generic or no lubricants if not safe. |

| Cross-Pattern Tightening | Apply pressure evenly to avoid component skew. | Tighten bolts in a random order. |

Faulty fastening is a silent culprit behind many service calls in electric bike repair. By adhering to these guidelines with diligence and precision, each rider ensures stability and prolongs the life of key parts. Ultimately, proper fastening directly contributes to a smoother, safer riding experience.

Regular monitoring and proactive adjustments based on first-hand mechanics' observations help avoid potential mishaps. We have encountered countless instances of damage that might have been averted by routinely checking bolt tightness. In conclusion, proper fastening is not a one-off task but an ongoing part of electric bike maintenance that demands attention at every repair session.

Mistake #2: Poor Battery Maintenance and Charging Errors

The e-bike battery is the central lifeline of your electric cycle. Errors related to battery maintenance can dramatically reduce capacity and overall efficiency.

Common charging mistakes include overcharging, deep full discharges, and storing the battery in environments with extreme temperatures. Overcharging, especially when persistent, has been observed to degrade battery cells even when modern battery management systems are involved. Data indicate that improper charging cycles can reduce battery capacity by up to 20% over a one-year period.

For optimal performance, batteries should be charged within the recommended voltage range and kept at moderate charge levels when not in use. It is critical to avoid letting the battery fully discharge regularly. Experienced technicians emphasize that maintaining a charge between 20% and 80% prolongs the battery life.

A practical checklist for battery charging includes using a charger approved by the e-bike's manufacturer. Always monitor charging sessions actively rather than leaving the battery unattended overnight. For instance, data points from several models have shown that batteries managed with such protocols can achieve a cycle life exceeding 500 full cycles.

When storing your battery, temperature control is essential. Avoid environments that are overly humid or excessively hot. A simple bullet list summarizes the do's and don'ts:

• Do use a charger that meets the manufacturer's specified output.

• Do store the battery in a cool, dry area at room temperature.

• Don't let the battery drain completely before recharging.

• Don't expose the battery to direct sunlight or heat sources.

• Do inspect battery contacts frequently and clean them with a soft, dry cloth.

• Don't use abrasive cleaning materials that might harm sensitive components.

Furthermore, riders should incorporate regular battery diagnostics into their electric bike repair routines. Checking voltage readings and monitoring temperature during charge cycles have proven beneficial in early fault detection. Many workshops now use battery analyzers that help identify potential issues such as unexpected voltage drops or overheating cells.

In the field, experienced riders report that recalibrating battery management systems after several charge cycles is a beneficial practice. Statistics from recent studies indicate that a properly maintained battery not only extends the riding range but also significantly reduces the risk of failures during critical moments. Some e-bike repair experts advise replacing the battery if it does not meet the performance benchmarks after a certain number of cycles, typically around 500 cycles.

Practical examples from professional service centers reveal that neglecting proper battery maintenance usually results in erratic motor performance and intermittent power. Routine visual inspections help in identifying corrosion or swelling which are early indicators of battery life deterioration. Overall, improved battery maintenance practices translate into longer riding times and a more reliable electric bike experience.

Mistake #3: Faulty Wiring and Connector Neglect

Faulty wiring is a frequent culprit behind intermittent electrical issues on electric bikes. Loose connectors or frayed wires often lead to erratic motor output and unexpected system shutdowns.

A visual inspection of wiring components is vital during routine electric bike repair. Riders should perform a systematic check starting from the battery connection, moving through the controller, and examining all connectors along the frame. Any signs of wear or fraying signal the need for immediate intervention before a minor issue escalates into a major failure.

A practical checklist for wiring inspection involves several detailed steps. Begin by ensuring that all connectors are firmly in place and that electrical insulation is intact. A common first-hand observation from experienced mechanics is that even minor vibrations during riding can loosen a connector over time.

For effective troubleshooting, we recommend the following diagnostic steps:

1. Visually inspect all cables for signs of wear, kink, or abrasion.

2. Use a multimeter to test continuity on all wiring segments.

3. Re-seat any loose connectors, ensuring a secure fit.

4. Replace any wires that exhibit visible damage or compromised insulation.

Small connectors and wiring bundles deserve particular attention given the harsh environmental conditions experienced during rides. Moisture ingress through damaged insulation can lead to short circuits or corrosion on sensitive electronic components. Many seasoned repair experts highlight that neglecting even one faulty connector can lead to repeated failures and costlier repairs down the line.

Routine preventive maintenance assists in detecting issues early. A recommended practice is to schedule wiring checks every few months, especially if the bike is used in wet or muddy conditions. Documenting the condition of wiring during each service call helps track its deterioration over time.

Some repair workshops use cable ties to secure loose wiring along the frame for extra protection against movement. Additionally, insulating sleeving can be installed on worn segments to prevent further damage. A visual aid in the form of a checklist or flowchart can be particularly useful for riders performing self-diagnosis of wiring issues.

Data from field studies suggest that 15–20% of recurring e-bike malfunctions stem directly from improper wiring practices. This reinforces the necessity of treating wiring and connectors as precise, vital components of the overall electrical system. Meticulous attention to these details ensures a stable, reliable connection throughout the bike's operational life.

By following these troubleshooting steps, riders can prevent common wiring issues that disrupt the electrical circuit. Early diagnosis and prompt repair of any observed faults contribute significantly to the longevity and safety of your electric bike. Investing time in proper wiring checks ultimately saves both time and money in the maintenance cycle.

Mistake #4: Inadequate Cleaning Techniques and the Use of Harsh Chemicals

The aesthetics and functionality of an electric bike largely depend on proper cleaning techniques. Using harsh chemicals or improper cleaning methods can damage sensitive components and degrade critical materials.

Many riders mistakenly assume that any cleaning agent will suffice. However, only bike-specific cleaners or mild soapy water are best suited for cleaning. Harsh chemicals such as bleach and industrial solvents can corrode metal surfaces and weaken plastic components.

A comparative analysis of cleaning solutions reveals that bike-specific cleaners maintain the integrity of aluminum frames and electronic display surfaces. A practical cleaning regimen should include the following steps:

• Rinse the e-bike with low-pressure water to remove loose dirt.

• Use a soft brush with soapy water to gently scrub the frame.

• Avoid using power washers that can force water into electrical ports.

• Dry the bike immediately with a microfiber cloth to prevent moisture accumulation.

A key observation from field experts is that over-washing and prolonged exposure to water may lead to rust formation on metal parts. Many service centers advise a regular cleaning schedule that avoids daily washing with harsh chemicals. Instead, periodic deep cleans using appropriate cleaners are sufficient to maintain performance.

It is also essential to pay attention to components such as the battery compartment and electronic connectors. These areas require extra caution as water ingress can lead to short circuits or battery damage. An effective strategy is to use a bike cover during heavy rain rather than cleaning immediately after exposure.

A table comparing cleaning agents is useful:

| Cleaning Agent | Suitable For | Not Recommended For |

| Bike-Specific Cleaners | Aluminum, plastics | Sensitive electrical components |

| Mild Soapy Water | General cleaning | Areas requiring delicate care |

| Power Washers | Outdoor surfaces only | Direct contact with electronics |

| Harsh Chemicals (Bleach) | Rarely recommended | Metal frames, plastic parts |

Implementing correct cleaning techniques reduces maintenance-related issues and preserves the bike's value. Every repair station stresses the significance of following manufacturer guidelines for cleaning. Reports from experienced mechanics show that bikes cleaned with proper methods maintain smoother performance and exhibit lower rates of corrosion.

In summary, the choice of cleaning agent, along with the method of application, directly influences the longevity of an e-bike's components. We recommend incorporating gentle cleaning techniques as a standard practice in your maintenance routine. This proactive approach helps extend component life and ensures that the bike remains in optimal condition.

Mistake #5: Neglecting Brake and Drivetrain Maintenance

The brake system and drivetrain are safety-critical aspects of every electric bike. Neglect in these areas can lead to decreased performance, premature wear, and even dangerous riding conditions.

Common mistakes include using incorrect brake pads, misaligned rotors, and not adjusting cable tensions as needed. Drivetrain issues, such as misalignment of the chain, cassette, or derailleur, can cause inefficient power transfer and cause increased wear over time. Statistical data from maintenance logs indicate that nearly 25% of e-bike faults are related to brake or drivetrain issues.

Regular inspection of brake pads, rotors, and cable housings is vital. A well-maintained brake system ensures safe stopping power and reduces the risk of accidents. Frequent checks help identify wear signs early—such as thinning brake pads or warped rotors—which can be immediately replaced.

A detailed maintenance checklist for brakes and drivetrain should include:

• Inspecting brake pads for worn material and replacing them every 3–6 months, depending on usage.

• Checking rotor alignment to ensure even wear.

• Verifying cable tension and making adjustments as cables extend over time.

• Inspecting the chain, cassette, and derailleur for any signs of misalignment or excessive wear.

Some repair experts recommend using high-quality replacement parts that adhere to manufacturer recommendations. Data collected from multiple maintenance centers demonstrates that bikes serviced with premium components exhibit fewer malfunctions. For instance, a recommended interval for routine brake inspection is every 500 miles of riding, with adjustments as necessary.

Drivetrain alignment is equally critical. Misaligned chains can skip or cause rough shifting, leading to inefficiencies during rides and potential damage. We advise riders to use derailleur adjustment tools and alignment gauges to maintain optimal settings.

A step-by-step procedure for drivetrain maintenance might include:

1. Removing the chain for a detailed inspection.

2. Cleaning the chain, cassette, and chainrings thoroughly.

3. Reinstalling the chain and testing for smooth gear transitions.

4. Adjusting derailleur limit screws to prevent over-shifting.

A checklist summary for brake and drivetrain maintenance:

| Maintenance Task | Recommended Interval | Key Observation |

| Brake Pad Inspection | Every 500 miles | Look for thinning of pad material and uneven wear. |

| Rotor Alignment | Monthly | Ensure rotors are straight and not warped. |

| Cable and Housing Check | Every 3 months | Inspect for signs of fraying or slack in tension. |

| Drivetrain Cleaning & Adjustment | Every 300-500 miles | Check chain wear and ensure smooth gear shifting. |

Experienced repair centers have repeatedly stressed that even minor neglect in brake and drivetrain maintenance can result in costly repairs and compromised safety. Riders who adhere to a strict maintenance schedule report significant improvements in both performance and riding confidence. In-depth diagnosis using visual cues and performance tests provides immediate feedback on the state of these critical systems.

Ultimately, neglecting brake and drivetrain maintenance is not worth the risk. Regular checks, coupled with the use of correct adjustment tools, guarantee that your bike remains safe and performs at its best. These preventative measures have proven to markedly extend component life and ensure a secure riding experience.

Conclusion

In summary, the top 5 electric bike repair mistakes include improper bolt fastening, poor battery maintenance, neglect of wiring and connectors, inadequate cleaning techniques, and failure to maintain brakes and drivetrain systems. Each error, while seemingly minor, can accumulate to compromise overall safety and performance.

We encourage riders to adopt these strategies to minimize downtime and extend the lifespan of their e-bikes. Sharing experiences and engaging with the broader community can further refine best practices. By addressing these common pitfalls head-on, every rider can enjoy a safer and more reliable ride. Embrace proactive electric bike repair practices and keep your machine performing at its peak every time you ride.

FAQs

1. What are the most common fastening mistakes made during electric bike repairs?

The most common fastening mistakes include under-tightening bolts (causing components to loosen during rides) and over-tightening bolts (damaging threads and causing premature wear). Always use a calibrated torque wrench and follow manufacturer's specifications to avoid these issues.

2. How should I properly maintain my electric bike battery in 2025?

Maintain your e-bike battery by keeping charge levels between 20-80%, using manufacturer-approved chargers, storing at room temperature in dry conditions, avoiding complete discharge, and regularly inspecting contacts. Modern batteries can achieve 500+ cycles with proper care.

3. What wiring issues commonly affect electric bikes and how can I prevent them?

Common wiring issues include loose connectors, frayed wires, and moisture damage leading to erratic motor performance. Prevent these by regularly inspecting all cables and connectors, using a multimeter for continuity tests, securing loose wires with cable ties, and scheduling wiring checks every few months.

4. What cleaning techniques should I avoid when maintaining my electric bike?

Avoid using harsh chemicals like bleach or industrial solvents, high-pressure water systems directed at electrical components, and excessive washing. Instead, use bike-specific cleaners or mild soapy water, soft brushes, and microfiber cloths to prevent damage to sensitive parts.

5. How often should I maintain my e-bike's brakes and drivetrain?

Inspect brake pads every 500 miles and replace them every 3-6 months depending on usage. Check rotor alignment monthly, cable tension quarterly, and clean and adjust the drivetrain every 300-500 miles. Regular maintenance prevents costly repairs and ensures optimal safety.

Leave a comment