How to Mount a Bicycle Front Rack Without Damaging Your Bike

The Challenge of Front Racks

Mounting a front bicycle rack can feel scary. The fear of scratching your paint, crushing a fork tube, or hurting your bike's strength is real and makes sense. Many riders want the usefulness of a front rack but wait, worried about causing damage that can't be fixed.

Let's make this clear: you can mount a front rack safely without any problems. The secret isn't about using lots of force or fancy tools. It lies in a simple, step-by-step approach: correctly finding out what your bike can handle and choosing a rack that fits perfectly. You can avoid guessing and potential damage by following three key stages:

- Checking Your Bike: Understanding your fork's material and existing mounting points.

- Choosing the Right Rack: Matching the rack's design to your bike's specific features.

- Proper Installation Method: Following a safe, step-by-step process with the right tools.

This guide will walk you through each stage, making sure your bike and your new rack work together perfectly.

Your 5-Minute Pre-Purchase Check

Before you even add a front bicycle rack to your shopping cart, this five-minute check is the most important step to prevent damage. It helps you understand your bike's design and make a smart choice.

1. Find Your Fork Mounts

Look closely at your front fork. The easiest and most secure way to mount a rack is by using dedicated mounting points known as braze-ons or eyelets. These are small, threaded holes made just for racks and fenders. You'll usually find them in two places:

* Lower Eyelets: Near the front axle dropout.

* Mid-Fork Eyelets: About halfway up the fork blades.

If your fork has these, you're in a great spot. If not, don't worry—the next section covers solutions for forks without eyelets.

2. Find Out Your Fork Material

The material of your fork decides which mounting methods are safe.

* Steel: A magnet will stick to it. Steel is strong and bends well, making it the most forgiving material for different mounting solutions, including clamps.

* Aluminum: A magnet will not stick. It's lighter and stiffer than steel but can crack more easily from focused clamping pressure.

* Carbon Fiber: A magnet will not stick. It often has a woven look and feels like plastic when tapped. This material is very strong for riding forces but can be crushed easily. You need to be extremely careful.

3. Check Your Brake Type

Your brake system can get in the way of a rack's support arms.

* Disc Brakes: The caliper is mounted on the fork leg and can block a rack's lower supports. Many modern racks are disc-compatible with designs that curve around the caliper.

* Rim Brakes (V-brakes/Cantilever): These brakes are mounted on posts on the fork blades. While less of a problem than disc brakes, you must make sure the rack's arms don't hit the brake arms or cables.

4. Measure Tire and Fender Space

Make sure there's enough space between your tire and the bottom of the fork crown, as well as around any existing fenders. The rack's mounting hardware and crown bracket need room to be installed without rubbing against the tire or fender.

| Bike Checkpoint | What to Look For | Why It Matters for a Front Rack |

|---|---|---|

| Fork Eyelets | Threaded holes at dropouts, mid-fork | Easiest & strongest mounting method. |

| Fork Material | Carbon, Aluminum, Steel | Determines safe mounting options (especially clamping). |

| Brake System | Disc vs. Rim Brakes | Potential for physical interference with rack struts. |

| Tire/Fender Clearance | Space around the tire | Ensures the rack and its hardware will fit. |

Mounting Racks Without Eyelets

What if your fork has no eyelets? This is common for road, gravel, and many hybrid bikes. Luckily, many excellent adapter solutions exist. Here's a breakdown of your best options.

Option 1: P-Clamps (Rubber-Lined Clamps)

How it Works: P-clamps are simple, rubber-lined metal bands that wrap around your fork legs to create a mounting point. The rubber lining is important for grip and paint protection.

Best For: Steel and sturdy aluminum forks carrying light-to-moderate loads (like a small basket for commuting, not for heavy-duty touring).

Damage Risk: Low to moderate. The main risks are tightening too much, which can dent or crush a fork tube (especially on thin-walled aluminum), and dirt working under the clamp, which can scratch the paint over time. Never use P-clamps on a carbon fiber fork. We've found that wrapping a layer of old inner tube under the P-clamp adds extra protection and grip, but you must regularly check for paint damage.

Option 2: Axle-Mounting Adapters

How it Works: This smart solution replaces your wheel's standard quick-release skewer or thru-axle with a new, longer one that has threaded ends. The rack then bolts directly onto these extended axle ends, creating a very secure lower mounting point.

Best For: Almost any bike, including those with carbon or suspension forks where clamping is not an option. This is the gold standard for adding a rack to a bike not designed for one, a system pioneered by rack specialists like Old Man Mountain.

Damage Risk: Very low for the fork. The load goes to the axle, which is designed to handle it. The only risk comes from using a low-quality adapter or wrong installation, which could make wheel security unsafe. Always use a high-quality kit and tighten it to the manufacturer's specifications.

Option 3: Handlebar and Brake-Boss Mounts

How it Works: Some racks, especially porteur-style platform racks and baskets, don't use fork leg mounts at all. They use a combination of attachment points, often bracing against the handlebars and bolting to the fork crown hole or, for bikes with rim brakes, the cantilever brake bosses.

Best For: Commuter bikes, city bikes, and cruisers where the goal is to carry a basket or a platform load in front of the handlebars.

Damage Risk: Low. The main things to consider are making sure the mounts don't interfere with or pinch brake and shifter cables. A wrongly loaded rack of this type can also affect steering more, so it's best for moderate loads. For heavy loads on bikes without eyelets, a method tested by long-distance cyclists involves using high-strength GBS clamps, but this is an advanced technique.

Fork Material Safety Guide

Understanding how your fork material acts under stress is critical for preventing serious failure. Clamping forces are very different from the riding forces a fork is designed to handle.

Carbon Forks: The "Do Not Clamp" Rule

Carbon fiber's amazing strength-to-weight ratio comes from long, continuous fibers set up to handle the forces of riding, braking, and cornering. However, it is not designed to resist sideways crushing forces from clamps. A clamp creates focused pressure that can easily crack the resin and separate the underlying carbon fibers, leading to sudden and complete failure.

Let's be clear: Do not use P-clamps or any other clamping device on a carbon fiber fork unless the fork and rack manufacturers clearly approve it for your specific model. If your carbon fork has built-in eyelets or is compatible with an axle-mount system, those are your only safe options.

Aluminum Forks: Be Careful

Aluminum is a strong and lightweight metal, but it is more brittle than steel. It doesn't bend much before it breaks. While P-clamps can be used on many aluminum forks, they must be used correctly. Make sure the clamp is the right diameter, the rubber lining is thick, and you do not over-tighten the bolt. Use a torque wrench if possible. Regularly check the area under the clamp for any signs of paint cracking or metal fatigue.

Steel Forks: The Most Forgiving Option

Steel is the workhorse of the cycling world. Its ability to bend means it can flex under load without breaking, making it far more resistant to clamping forces than aluminum or carbon. It is the safest material for use with aftermarket solutions like P-clamps. While it's still possible to damage a steel fork by extreme over-tightening, it is much more tolerant and provides a wider margin for error, making it the ideal choice for custom front bicycle rack setups.

Safe Installation Step-by-Step

You've done the assessment and chosen the right rack. Now, it's time for a clean, secure installation. Rushing this final step is where bolts get stripped and parts get scratched.

1. Gather Your Tools: You will typically need a set of metric Allen keys (hex wrenches), a small adjustable wrench, and potentially a socket set. Most importantly, use a torque wrench if you have one. It is the single best tool for preventing damage from over-tightening. Also, have some blue thread locker on hand.

2. Prepare the Bolts: Put a single drop of blue (medium strength) thread locker on the threads of each bolt. This acts like a lock washer, preventing the vibrations of riding from loosening the bolts over time.

3. Loosely Attach Lower Mounts: Start by attaching the rack's lower arms to the fork's dropout eyelets, P-clamps, or axle mounts. Thread the bolts in by hand just a few turns so the rack is supported but can still move freely. Do not tighten them yet.

4. Loosely Attach Upper Mounts: Connect the upper support arms or crown bracket to their matching mounting points (fork crown, mid-fork eyelets, or brake bosses). Again, just thread the bolts in enough to hold things in place.

5. Level and Center the Rack: With all bolts loose, you can now position the rack. Stand in front of the bike and look at the rack to make sure it is centered over the front wheel. Look from the side to make sure the top platform is level with the ground. Gently adjust the rack's position until it is perfect.

6. Tighten to Spec: Begin to tighten all the bolts in an alternating pattern, like tightening lug nuts on a car wheel. Don't fully tighten one bolt all at once. Snug them up gradually, moving from one to another. This makes sure the rack settles evenly without stress. Use a torque wrench to apply the final tightening to the manufacturer's recommended specification. If no spec is given, a general rule is "snug plus a quarter turn"—tight enough that it won't move, but not so tight you feel the bolt straining.

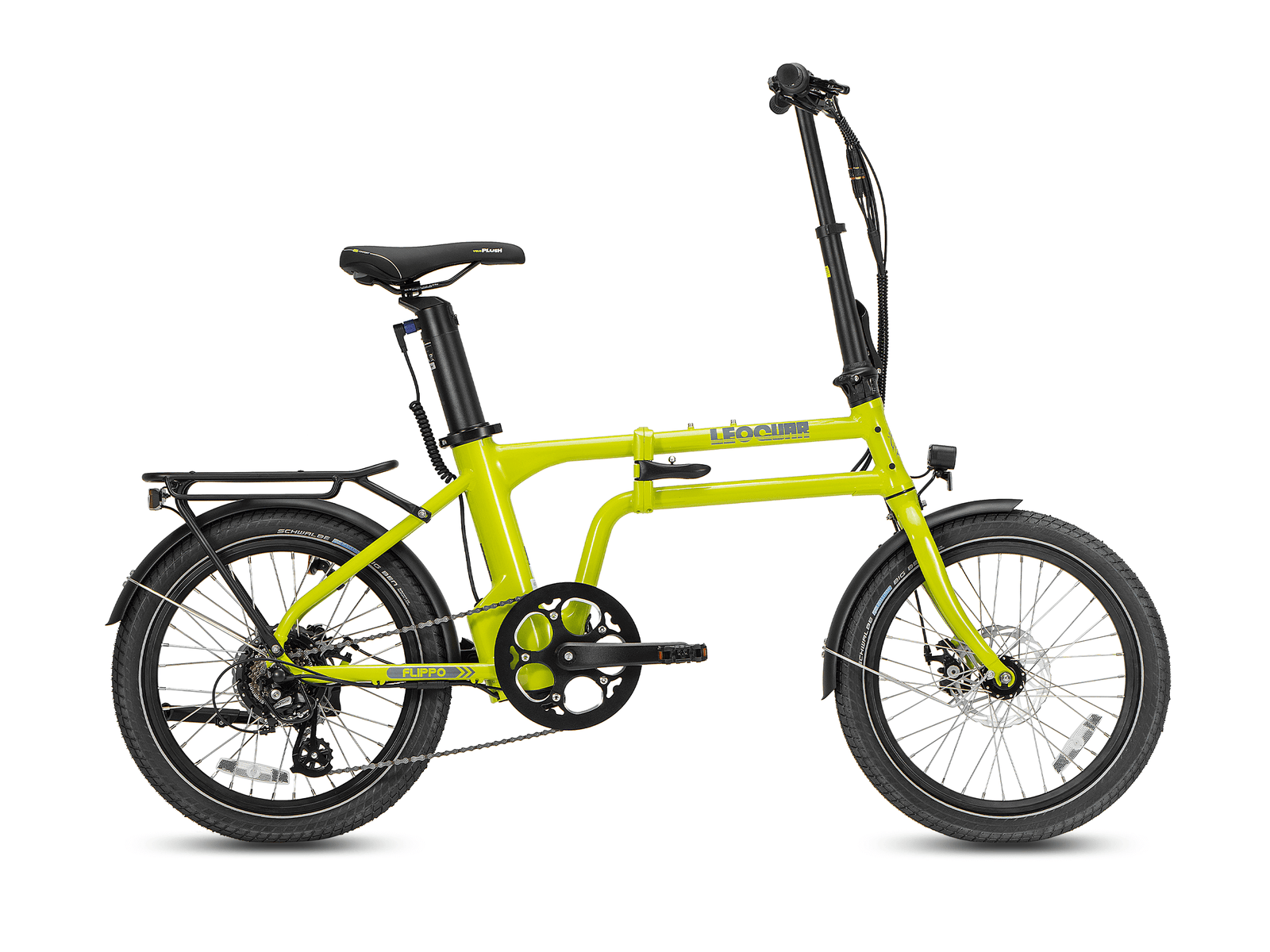

Mounting a front rack the right way means keeping your bike safe while adding real carrying power. The Leoguar Flippo Front Basket is built to fit securely, distribute weight evenly, and protect your frame — so you get extra storage without the worry of damage.

Front Rack FAQ

1. How much weight can a front bicycle rack hold?

This varies a lot. A basic rack mounted with P-clamps might be rated for only 10 lbs (4.5 kg), while a heavy-duty touring rack bolted to dedicated eyelets can hold 55 lbs (25 kg) or more. Always check the rack manufacturer's weight limit and never go over it. The mounting method is often what limits the weight capacity.

2. Will a front rack change my bike's steering?

Yes, especially when loaded. Weight on the front wheel increases steering resistance, making the handlebars want to fall to one side at low speeds and feel heavier at high speeds. This is normal and you'll get used to it quickly, but it's best to start with a light load to feel the difference. Low-rider racks that put weight closer to the axle have less impact on steering than platform racks that place weight up high.

3. Can I use a rear rack on the front?

Generally, this is not a good idea. Rear racks are designed for the specific shape and mounting points of a bike's rear triangle. The width, arm length, and angles are all different. While some experienced mechanics have made it work on certain steel bikes with custom changes, it is not a safe or recommended practice for most cyclists. Always buy a rack made specifically for front mounting.

4. Do I need special tools to install a front bicycle rack?

Most installations require basic tools: metric Allen keys, an adjustable wrench, and possibly a socket set. A torque wrench is highly recommended to prevent over-tightening and damage. You'll also want blue thread locker to keep bolts from loosening over time. The specific tools needed depend on your rack type and mounting method.

5. How do I know if my fork can safely support a front rack?

Check three things: fork material (steel is most forgiving, carbon requires extreme caution), existing mounting points (eyelets are best), and brake compatibility (disc brakes may interfere with some rack designs). Steel forks with dedicated eyelets are ideal, while carbon forks should only use axle-mount systems or manufacturer-approved mounting methods. When in doubt, consult a bike shop professional.

Leave a comment