Bike Shifter Cable: Everything You Need to Know

That Annoying Moment When Your Bike Won't Shift

You press the shifter, but instead of a clean gear change, you get a grinding noise. It's a common problem that can ruin a good ride, but the fix is often simpler and cheaper than you think. The culprit is usually the unsung hero of your drivetrain: the bike shifter cable.

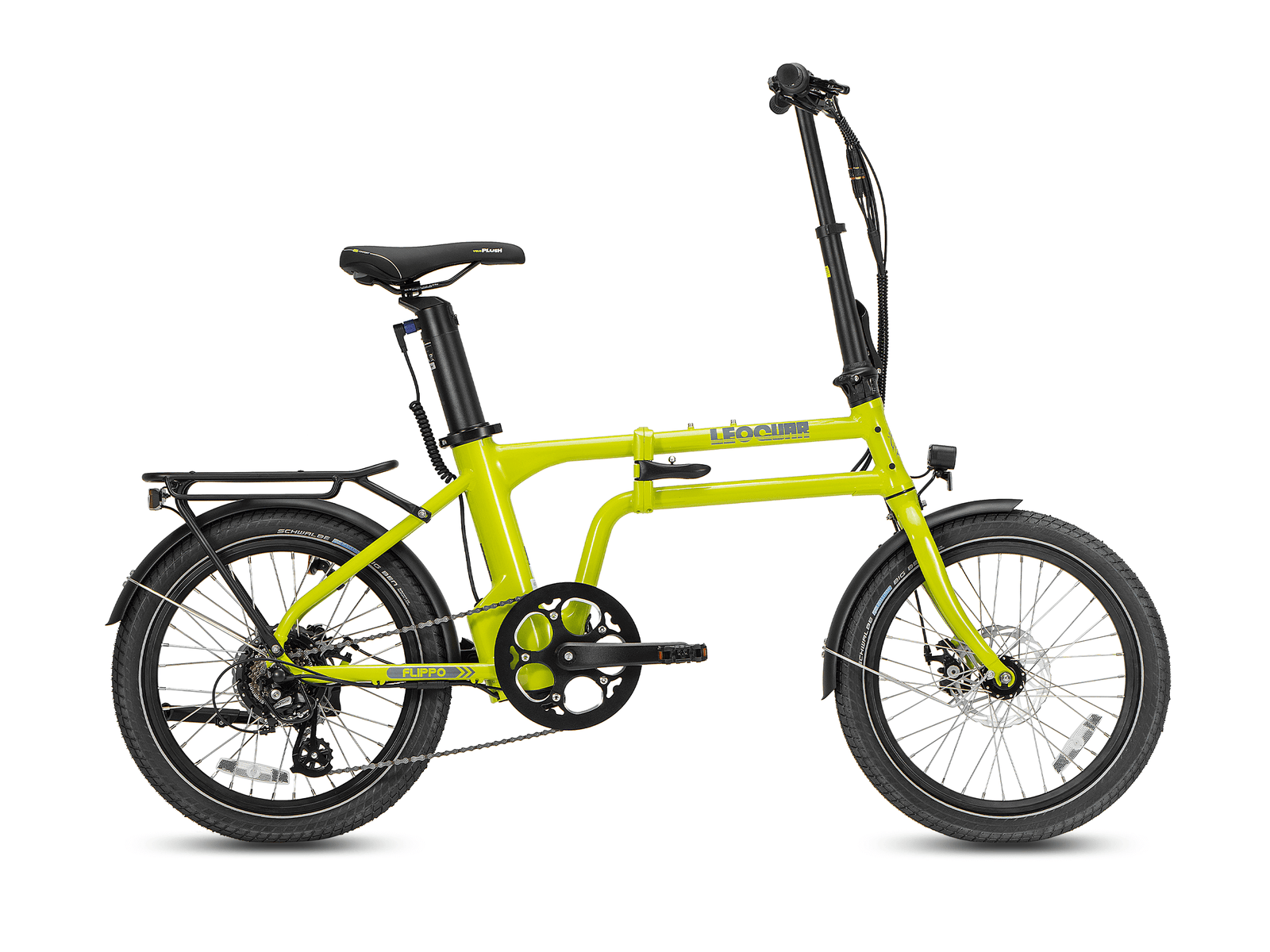

This guide will help you understand, find, diagnose, and fix your shifter cables. A shifter cable is a thin steel wire that connects your shifter lever to your derailleurs. It runs from the shifters on your handlebars, along or inside your e bike frame, and ends at the front and rear derailleurs, which move your chain between gears. When this system works well, it's invisible. When it fails, your ride stops working. Let's fix your bike so it shifts perfectly again.

What and Where

The Shifter's Messenger

A shifter cable is basically a messenger. Think of it as the nervous system connecting your command at the handlebar to the action at the gears. When you click your shifter to move to an easier gear, the shifter pulls a tiny amount of the inner cable. This increase in tension moves the derailleur cage, which guides the chain onto a larger cog on your cassette.

When you shift to a harder gear, the shifter releases some cable. The derailleur's spring tension then pulls it back, moving the chain to a smaller cog. This careful balance of pulling and releasing tension allows for indexed shifting—the clean "click" into each gear that we expect. Without a working shifter cable, this communication breaks down, leading to all the shifting problems we want to solve.

Finding The Cable

Finding the shifter cable on your bike is easy once you know its path. Let's trace it from start to finish.

- It begins inside your shifters, which are on your handlebars. On a flat-bar bike, they are separate pods, while on a road bike with drop bars, they are built into the brake levers.

- The cable then exits the shifter and enters a protective outer sleeve called the housing. This housing runs along the bike's frame.

- On many bikes, it is routed externally, held in place by small clips or guides on the down tube or top tube. On newer bikes, it may be routed internally, disappearing into a port on the frame and traveling hidden inside the tubes.

- Finally, the housing stops at a "cable stop" near the derailleur. A short, exposed section of the inner wire then comes out, runs to the derailleur, and is held in place by a small anchor bolt.

You will have one cable system for your rear derailleur and, if you have multiple front chainrings, a second system for your front derailleur.

Parts of the System

A shifter cable is more than just a single wire; it's a complete system where every small part matters. Understanding these parts helps you find problems more easily.

The Inner Cable: This is the steel wire that does all the work. It's usually made of stainless steel to resist rust, and some high-end versions have a special coating for smoother action. Inner cables have different "heads" or anchor ends. Shimano and SRAM generally use one type, while Campagnolo uses a slightly different shape. You must use the correct one for your shifters.

The Housing: This is the protective outer sleeve. Its job is to provide a smooth, protected path for the inner cable to run through. For modern shifting, "compressionless" housing is the standard. It's built with steel strands that resist being squashed when the cable is under tension, which is important for precise shifts.

The Ferrules: These are the small metal or plastic caps that fit onto the ends of the housing segments. They might seem small, but they are important. Ferrules provide a solid, clean connection between the housing and the frame's cable stops or the barrel adjuster on the derailleur. They prevent the housing's steel strands from flaring out and creating friction.

The Cable End Crimp: This is the tiny aluminum cap that you crimp onto the very tip of the inner wire after it has been installed and trimmed. Its purpose is to prevent the steel cable from unraveling and fraying, which keeps it clean and makes future adjustments much easier.

Signs of Failure

Your bike will usually tell you when its shifter cable needs attention. Learning to spot these symptoms can help you fix issues before they lead to complete failure. Here are the most common signs:

Slow or Hesitant Shifting: This is the most frequent symptom. You press the shifter, but there's a delay before the gear actually changes. This is often caused by increased friction within the system. Dirt, grime, or moisture has worked its way into the housing, or the inner wire is starting to wear out, preventing it from sliding smoothly.

Ghost Shifting: Your bike seems to have a mind of its own, shifting gears randomly, especially when you hit a bump or put down a lot of power. This can be caused by a few things, but incorrect cable tension or housing that is too short and pulls on the derailleur are common problems related to the shifter cable.

Inability to Shift: The shifter lever feels either completely stuck or mushy and loose, and you cannot shift into certain gears. If you can't shift to harder gears (smaller cogs), the cable might be dirty or frayed inside the housing. If you can't shift to easier gears (larger cogs), the cable may have snapped or stretched too much.

Grinding and Noise: The chain constantly makes a rattling or grinding noise because it's not sitting perfectly centered on a cog. This is a classic sign of poor indexing, which is directly managed by shifter cable tension. The cable has likely stretched slightly over time, throwing off the precise alignment.

Visible Fraying or Rust: The easiest diagnosis of all. Take a look at the exposed section of inner wire near your derailleur. If you see any broken wire strands or signs of rust, it is definitely time for a replacement.

The very first indicator is often a subtle change in the feel at the lever. A new, clean shifter cable system feels crisp and responsive. When it starts to feel "spongy" or soft, that's the first sign that friction is building up and maintenance is due.

Step-by-Step Replacement

Replacing a bike shifter cable is a great skill for any cyclist to learn. It saves you money and helps you keep your bike in top condition. With the right tools and a little patience, you can do this.

Getting Your Tools

Having the right tools makes the job go from frustrating to satisfying. You don't need a full professional workshop, but a few key items are important.

- New shifter cable and housing

- High-quality cable and housing cutters

- Allen keys (typically 4mm and 5mm)

- Needle-nose pliers or a dedicated cable puller

- A small pick or sharp awl

- Cable end crimps

A note on cutters: Do not try to use regular pliers or wire snips. They will crush the housing and fray the cable, creating more problems. A dedicated cutter designed for bike cables makes a clean, square cut that is vital for good performance.

The Replacement Process

Shift to the Smallest Cog. Before you do anything else, shift your rear derailleur all the way down to the smallest cog on the cassette. If you are replacing the front cable, shift to the smallest chainring. This action releases all the tension from the shifter cable, making it slack and easy to remove.

Snip and Remove the Old Cable. Use your cutters to snip off the old end crimp from the tip of the cable. Loosen the anchor bolt on the derailleur (usually with a 5mm Allen key) and pull the cable free. Now, push the cable from the derailleur end back towards the shifter. You will need to find the cable port on your shifter body—sometimes it's hidden under a small plastic cover—and pull the old cable completely out. Remove all the old housing segments from the frame.

Prepare the New Housing. This is the most important step. Use the old pieces of housing as a guide to measure and cut your new housing to the exact same length. "Measure twice, cut once" is the rule here. Use your dedicated housing cutters to make a perfectly square cut. After cutting, the inner plastic liner can get pinched shut. Using a pick to gently open up this liner is one of the most important professional mechanic techniques for ensuring low-friction performance. Finally, place new ferrules on both ends of each new housing segment.

Thread the New Cable. Take your new inner cable. You can apply a very thin layer of light grease or cable-specific lubricant to it, but don't overdo it. Carefully feed the headed end of the cable into the port on your shifter until it seats firmly inside. Then, thread the other end of the cable through your new housing segments and any internal frame guides.

Attach and Tension the Cable. Route the cable through the derailleur's guide path and pull it tight with your pliers or cable puller. While holding this tension, tighten the derailleur's anchor bolt to secure the cable. The goal is to have "finger tight" tension—no slack, but not so tight that you've already moved the derailleur.

Crimp the End. Shift through all the gears to make sure it's working. Once you're happy with the initial setup, use your cutters to trim the excess cable, leaving about 1 to 2 inches past the anchor bolt. Place a new end crimp over the tip and squeeze it firmly with your pliers to secure it.

Fine-Tuning for Perfect Shifts

After replacing a shifter cable, or as a standalone tune-up, you'll need to "index" your gears. This process fine-tunes the cable tension so that every click of the shifter results in a perfect gear change. The key to this is the barrel adjuster.

The Barrel Adjuster

The barrel adjuster is a small, knurled knob that the shifter housing fits into. You will find one on your rear derailleur, and sometimes also where the housing exits the shifter. Turning this knob effectively lengthens or shortens the housing, which makes tiny adjustments to the cable tension. It's the same principle as tuning a guitar string.

The Adjustment Process

The logic is simple. Remember that pulling the cable moves the chain to a bigger cog (easier gear).

- Turn Counter-Clockwise: This moves the adjuster out, increasing cable tension. Do this if the chain is hesitant to shift up to a larger cog.

- Turn Clockwise: This moves the adjuster in, decreasing cable tension. Do this if the chain is slow to drop down to a smaller cog.

A simple routine is to shift onto a middle cog in the back. Listen for any rattling. If the chain is trying to jump up to a bigger cog, turn the adjuster clockwise a quarter-turn at a time. If it's trying to drop to a smaller one, turn it counter-clockwise. Then, shift up and down the cassette. If the upshift is slow, give it a counter-clockwise turn. If the downshift is slow, a clockwise turn.

DIY vs. Hiring a Pro

Deciding whether to replace your shifter cable yourself or take it to a bike shop comes down to time, tools, and comfort level.

Choosing the DIY route is incredibly rewarding. You'll save on labor costs (typically $20-$40 per cable), gain a deeper understanding of how your bike works, and feel the satisfaction of fixing it yourself. It's a perfect project if you enjoy tinkering, are willing to invest in a few specific tools like cable cutters, and have the patience to work through the steps carefully. For bikes with external cable routing, this is a very manageable job for a beginner.

However, there are times when heading to a professional is the smarter choice. If you have a bike with complex internal cable routing, the job can quickly become frustrating without special tools like magnetic guides. If you are short on time, a good mechanic can do the job in a fraction of the time it would take a first-timer. Furthermore, if you've replaced the cable and still can't solve your shifting issues, a pro can diagnose deeper problems, like a bent derailleur hanger or worn-out drivetrain components, that you might miss. If your bike has electronic shifting (like Shimano Di2 or SRAM AXS), there are no physical cables, and any issues require a different, more technical approach best left to a trained mechanic.

Frequently Asked Questions

1. How often should I replace my shifter cable?

There's no fixed schedule, as it depends on mileage, riding conditions, and cable quality. A good rule is to check them every six months and plan on replacing them annually if you ride regularly, or immediately if you notice fraying or poor performance.

2. Are all shifter cables the same?

No, while most use a standard thickness, the anchor head at the shifter end differs. Shimano and SRAM use one standard, while Campagnolo uses another. You must buy the cable that matches your shifter brand.

3. Can I use a brake cable for my shifter?

Absolutely not. Brake cables are much thicker and have a different-shaped head. They will not fit into the shifter mechanism or housing and should never be mixed up.

4. What's the difference between internal and external routing?

External routing runs the cables on the outside of the frame and is easier to service but can collect more dirt. Internal routing hides the cables inside the frame for a cleaner look and better protection but is much more difficult to replace.

5. How do I know if my cable tension is correct?

Your bike should shift smoothly up and down through all gears with crisp, immediate response to shifter clicks. If shifts are slow or hesitant in either direction, or if you hear chain noise between gears, your cable tension likely needs adjustment using the barrel adjuster.

Leave a comment