Leoguar Electric Bike OEM Services: From Supply Chain to Branded Delivery

The Modern Ebike Supply Chain

You have a vision for a successful electric bike brand. This brand will captivate riders and carve out a space in a booming market. But between that vision and a satisfied customer lies a gap of complexity—the global ebike supply. Managing component sourcing, quality control, assembly, and international logistics is a huge task. This task can derail even the most promising startups. This is where a strategic Original Equipment Manufacturer (OEM) partnership becomes the best solution.

At Leoguar, we use over 20 years of dedicated ebike R&D and manufacturing experience. We transform your concept into a market-ready reality. We don't just build bikes; we build brands.

The journey of an ebike from concept to consumer is far more complex than most new brands expect. It's a global puzzle of sourcing, manufacturing, and logistics. A single weak link can hurt quality, delay timelines, and increase costs. Understanding this landscape is the first step toward building a strong brand.

From Raw Materials to Rider

An ebike begins as hundreds of individual parts sourced from suppliers around the world. The process involves multiple important stages. First, companies source raw materials like aluminum for frames. Then they manufacture the core "three-electric" system—the motor, battery, and controller. This system can account for 30-40% of the bike's total cost. Next comes fabricating and treating frames, assembling all components with precision, and finally navigating the complexities of global shipping. Each stage requires specialized knowledge and careful oversight.

Navigating Common Pitfalls

For a new brand, managing this process alone comes with many risks. Poor component quality from unvetted suppliers can lead to performance issues and safety problems. The shipping hurdles are huge, especially with the strict rules for shipping lithium-ion batteries. Furthermore, the ups and downs of international trade can introduce unexpected tariffs and duties. These challenges in the domestic e-bike supply chain can destroy a business model overnight. Without an experienced partner, you must navigate these problems alone.

What is Ebike OEM?

Understanding your manufacturing options is important. The most common models are Original Equipment Manufacturer (OEM) and Original Design Manufacturer (ODM). While they may sound similar, they represent completely different approaches to building your product and your brand. Choosing the right path is a strategic decision that will define your brand's potential for standing out and long-term growth.

Defining OEM vs. ODM

An OEM partnership means we build your unique product based on your specific designs and technical specifications. Your brand keeps full ownership of the intellectual property (IP). It's a team process where your vision comes to life through our manufacturing skills.

An ODM partnership involves selecting a pre-existing ebike model from our catalog and applying your branding to it. This approach is faster to market and requires less R&D investment. However, it offers limited ways to stand out from other brands that may use the same base model.

| Feature | OEM (Your Vision, Our Expertise) | ODM (Proven Design, Your Brand) |

|---|---|---|

| Design | Fully custom, based on your specifications. | Based on manufacturer's pre-existing models. |

| Intellectual Property | Owned exclusively by your brand. | Typically shared or owned by the manufacturer. |

| Differentiation | High; your product is unique in the market. | Low; competitors may sell similar models. |

| Time to Market | Longer, due to R&D and prototyping. | Shorter, as design is already complete. |

| Investment | Higher initial R&D and tooling costs. | Lower initial investment. |

| Partnership | Deep, collaborative, and long-term. | More of a transactional supplier relationship. |

Core Benefits of OEM

For brands serious about building a unique identity and a lasting presence, partnering with an experienced ebike OEM offers several strategic advantages. You can focus on what you do best—marketing, brand building, and connecting with your customers. We handle the huge complexity of manufacturing and the ebike supply chain. You instantly gain access to our two decades of engineering knowledge and our established network of top-tier component suppliers.

We provide a clear path to scale production. Whether you're starting with a small batch or planning for mass-market volumes, our production lines are ready to grow with you. You can use our economies of scale, optimized production processes, and supply chain relationships to achieve a competitive cost per unit. This happens without sacrificing quality.

The Leoguar OEM Blueprint

Transparency and trust are the foundations of a successful OEM partnership. To make the process clear, we've developed a six-step journey that guides our partners from a simple idea to a globally delivered product. This blueprint is our commitment to a structured, professional, and team-based experience.

Step 1: Consultation & Design

Our partnership begins with a detailed consultation. We work closely with your team to understand your vision, target audience, desired performance characteristics, and cost targets. Our engineers provide expert feedback to refine your designs for manufacturability, durability, and performance. This ensures the final concept is both innovative and practical.

Step 2: Strategic Component Sourcing

With a finalized design, we move to sourcing. An ebike is only as good as its weakest component. We use our long-standing relationships with leading component manufacturers like Shimano, Bafang, Tektro, and Samsung. We get high-quality, reliable ebike parts that meet your exact performance and budget requirements. We handle the vetting, negotiation, and logistics for hundreds of individual parts. This ensures a stable and high-quality ebike supply for your brand.

Step 3: Prototyping & Field Testing

We translate the digital design into a physical prototype. This is an important checkpoint for you to see, touch, and ride your ebike for the first time. Before you even receive it, our internal quality team puts the prototype through many rigorous tests. We simulate thousands of miles of real-world stress, evaluate motor and battery performance under load, and test frame integrity. This ensures it exceeds industry standards.

Step 4: Mass Production & QA

Once you approve the prototype, we move to mass production. This isn't just about scaling up; it's about maintaining absolute consistency. Our production facility operates with strict quality assurance (QA) protocols at every stage. We conduct incoming quality control on all components, in-process checks at key assembly points, and a comprehensive final inspection. Every single ebike that comes off the line gets this treatment.

Step 5: Safety and Compliance

Navigating the global landscape of ebike safety standards is complex and required. We are experts in this area. We manage the entire process of testing and certification to ensure your products meet important regional requirements. This includes the UL 2849 safety standards for the complete ebike electrical system in North America. This protects your brand, your retailers, and your customers.

Step 6: Branded Packaging & Logistics

The final step is delivering your product safely and professionally. We work with you to design custom, durable packaging that protects the ebike during transit and creates a premium unboxing experience. Our logistics team then manages the entire shipping process, from factory floor to your destination warehouse. We handle freight, customs clearance, and duties to ensure a smooth, predictable delivery.

A Partnership for Growth

Our role doesn't end when the container ships. We believe a true OEM partnership is a long-term relationship built for sustained growth. We go beyond manufacturing to provide support and insights that help your brand thrive in a competitive market.

Post-Production Support

A brand's reputation is built on post-purchase support. We help you build that foundation. We work with you to establish a spare parts program. This ensures you have a reliable ebike supply of critical components like batteries, controllers, and displays to service your customers effectively. We also provide detailed technical documentation and can offer training for your customer service and technician teams. This empowers them to handle inquiries and repairs with confidence.

Market Insights and R&D

Our position at the heart of the ebike industry gives us a unique view of emerging technologies and market trends. We see firsthand the next generation of motor technology, advancements in battery chemistry, and new design philosophies. We share these valuable insights with our partners. This helps you anticipate market shifts and strategically plan your next product roadmap to stay ahead of the curve.

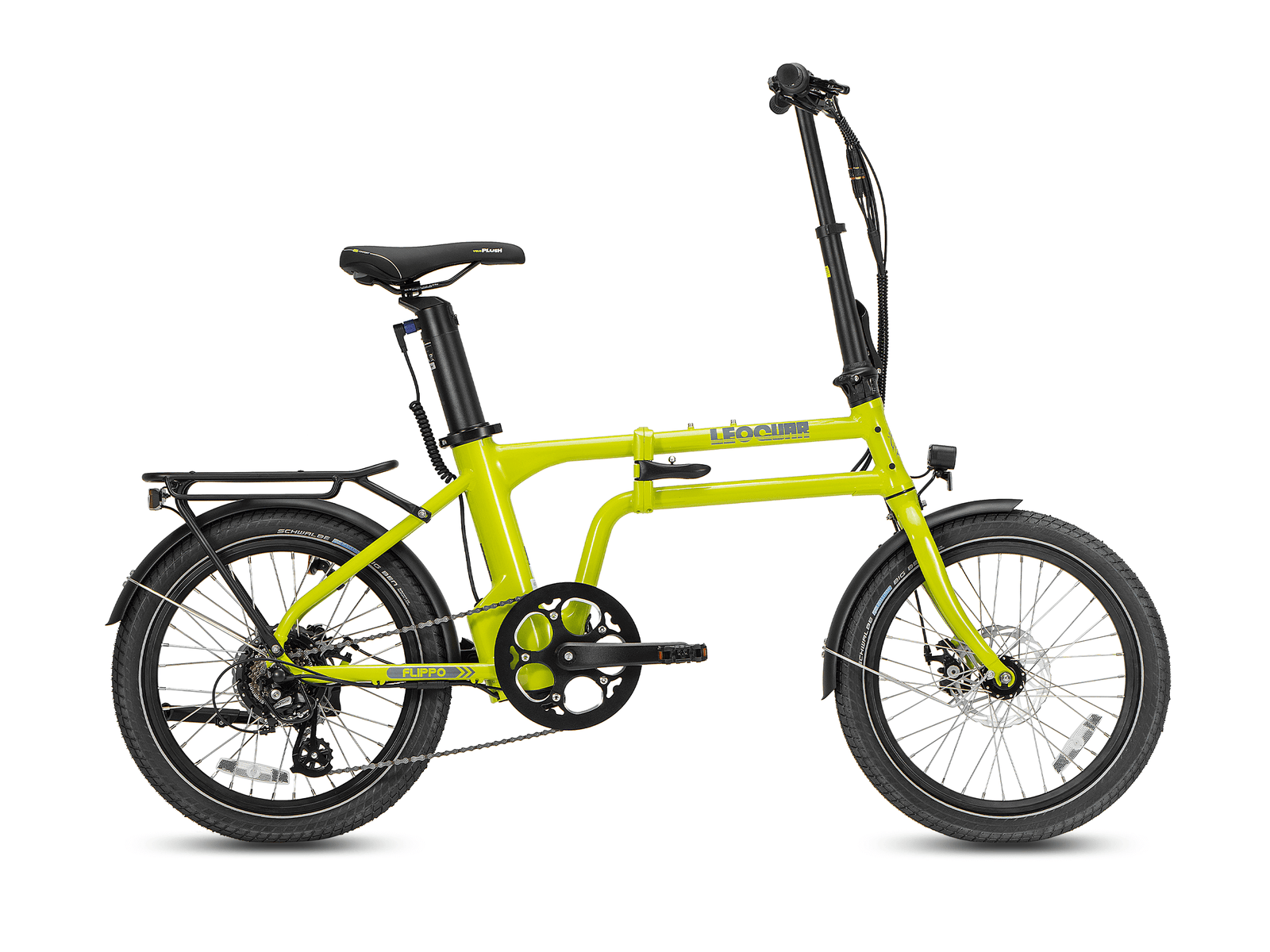

Case Study: A Startup's Success

Consider a startup with a powerful brand concept for a foldable, lightweight urban commuter ebike but no manufacturing experience. They partnered with Leoguar. We guided them through design refinement to optimize for weight and durability. We sourced a compact motor and a UL-certified battery that met their specific range targets, and managed the entire production process. The result: the brand launched on time, exceeded its quality goals, and is now working with us to scale production for expansion into European markets.

Why Choose Leoguar?

Choosing a manufacturing partner is one of the most important decisions you will make for your ebike brand. The right partner does more than just assemble parts; they provide a foundation for quality, scalability, and long-term success.

Your Vision, Our Foundation

With Leoguar, you are not just hiring a factory; you are gaining a partner with over 20 years of specialized experience. Our transparent OEM Blueprint ensures you have full visibility and control throughout the process. Our end-to-end service, from design consultation to global logistics, handles every aspect of the complex ebike supply chain. This frees you to focus on building your brand's story and community. We take your vision and build it on our foundation of expertise.

Let's Build Together

Your journey to launching a successful ebike brand starts with the right conversation. We are here to listen to your ideas, answer your questions, and show you how a strategic OEM partnership can turn your ambition into a tangible, high-quality product. Contact our OEM solutions team today to schedule your initial consultation and begin your journey.

FAQ

1. What is the difference between OEM and ODM for ebike manufacturing?

OEM means we build your unique product based on your specific designs and technical specifications. Your brand keeps full ownership of the intellectual property. ODM involves selecting a pre-existing ebike model from our catalog and applying your branding to it. OEM offers more customization and brand differentiation, while ODM is faster to market with lower initial investment.

2. How long does the OEM process take from design to finished product?

The timeline varies depending on the complexity of your design and customization requirements. Typically, the process takes 3-6 months from initial consultation to finished product. This includes design consultation, component sourcing, prototyping, testing, and mass production setup. We provide detailed timelines during the consultation phase.

3. What safety certifications do you handle for ebikes?

We manage the entire process of testing and certification to ensure your products meet regional requirements. This includes UL 2849 safety standards for the complete ebike electrical system in North America, CE marking for European markets, and other regional certifications as needed. Our expertise in global safety standards protects your brand and customers.

4. What is the minimum order quantity for OEM production?

Minimum order quantities depend on the level of customization and components required. For fully custom OEM designs, we typically work with orders starting at 100-500 units. For less complex customizations, smaller quantities may be possible. We discuss specific MOQ requirements during the consultation based on your unique project needs.

5. Do you provide ongoing support after production is complete?

Yes, we believe in long-term partnerships. We help establish spare parts programs, provide technical documentation, and offer training for your customer service teams. We also share market insights and emerging technology trends to help you plan future product development. Our support continues throughout your brand's growth journey.

Leave a comment