Electric Delivery Bikes Are Transforming Urban Logistics

A New Commerce Engine

The final mile of delivery is the hardest and most expensive part of shipping. Cities make this problem worse because of traffic jams, rising fuel costs, and pressure to protect the environment. These problems hurt profits and make customers unhappy for business owners and delivery workers.

A powerful solution is starting to change everything. The electric delivery bike is not just another option - it is reshaping how we deliver goods in cities. It combines speed, environmental benefits, and flexibility that regular delivery trucks cannot match. This article will look at this change from three important angles: the money and environmental benefits, how these bikes work better in crowded cities, and how to use them to make the most profit.

The Core Advantages

The business case for the electric delivery bike has three strong benefits. Any business that focuses on last-mile delivery will see these advantages turn into a stronger and more profitable business model. It helps the bottom line, the environment, and daily operations all at once.

Slashing Operational Costs

The biggest change when switching to an electric delivery bike is much lower operating costs. This money savings comes from several key areas:

Lower Fuel Costs: Charging an e-bike battery costs only cents, much less than a gallon of gas. A vehicle that runs all day can save thousands of dollars per year on fuel costs.

Reduced Maintenance: Electric motors have far fewer moving parts than gas engines. This means no oil changes, no spark plugs, no exhaust repairs, and much less routine maintenance. The main parts that wear out are brake pads and tires, which cuts service costs and downtime dramatically.

No Extra Fees: Delivery vans and scooters must pay for parking, tolls, and expensive parking tickets in busy city centers. An electric delivery bike can park on sidewalks or in bike racks, removing these costs completely.

Lower Starting Cost: A professional electric cargo bike costs much less than a commercial delivery van or even a new gas scooter. This makes it easier for new businesses and independent workers to get started.

Greening The Last Mile

The environmental benefits are powerful drivers for choosing electric bikes. Cities and customers want more sustainable practices, so an electric delivery bike fleet becomes a competitive advantage.

Zero Exhaust Emissions: Each electric delivery bike fights urban air pollution by producing no CO2, NOx, or particle emissions while running. This helps create healthier air for residents and workers.

Less Noise Pollution: The quiet electric motor helps create calmer, more livable city environments compared to the constant noise from delivery vans and scooters.

Smaller Carbon Footprint: The entire lifecycle impact, from making the bike to daily use, is much smaller. Studies show that replacing one diesel delivery van with an electric cargo bike can reduce CO2 emissions by over 5 tons each year. This gives companies real numbers for their sustainability reports.

Outsmarting Urban Congestion

In busy city streets, speed is not about going fast - it is about being nimble and getting access. This is where the electric delivery bike has a clear advantage.

Traffic Navigation: An electric delivery bike can legally use bike lanes and move through stopped traffic. Rush hour becomes an advantage instead of a problem.

Access to Restricted Areas: Many city centers, college campuses, and business parks have low-emission zones or ban cars completely. E-bikes can often access these areas, enabling true door-to-door service.

Faster Deliveries: The combination of easy navigation and almost no time spent looking for parking results in much shorter delivery times per stop.

More Deliveries Per Hour: In a dense city center, a rider on an electric delivery bike can complete more stops per hour than a driver in a van. This increases productivity and revenue potential.

Analyzing Unit Economics

To understand the real financial impact, we must look beyond general benefits and study the unit economics. For a delivery business, the unit is the vehicle. Comparing the total cost of ownership on a yearly basis shows how much better electric delivery bikes are for city routes. The following table shows realistic costs for a vehicle operating about 50 miles per day in a typical US city.

Comparing Delivery Tools

These numbers are based on national averages for fuel and energy costs. Maintenance estimates come from vehicle complexity and typical wear. These figures will vary by location and how much you use the vehicle, but the differences stay consistent.

| Cost Metric | Purpose-Built E-Cargo Bike | Gas Scooter (50cc) | Small Delivery Van |

|---|---|---|---|

| Initial Purchase Cost | $3,000 - $7,000 | $2,000 - $4,000 | $25,000 - $40,000 |

| Annual Energy/Fuel Cost | ~$150 | ~$750 | ~$2,500 |

| Estimated Annual Maintenance | ~$300 | ~$600 | ~$1,500+ |

| Insurance & Registration | ~$200 (Varies) | ~$400 | ~$2,000 |

| Annual Parking Costs/Fines | $0 | ~$250 (Estimated) | ~$1,200+ (Estimated) |

| Total Annual Operating Cost | ~$650 | ~$2,000 | ~$7,200+ |

The data is clear. Even when accounting for a higher purchase price compared to a basic scooter, the yearly operating cost of an electric delivery bike is less than one-third that of a gas scooter. It costs less than one-tenth that of a small van. For a business with ten vehicles, this means over $65,000 in yearly savings when replacing vans. The return on investment typically happens within the first year, especially when delivery volume is high and fuel and parking costs for traditional vehicles would be even higher.

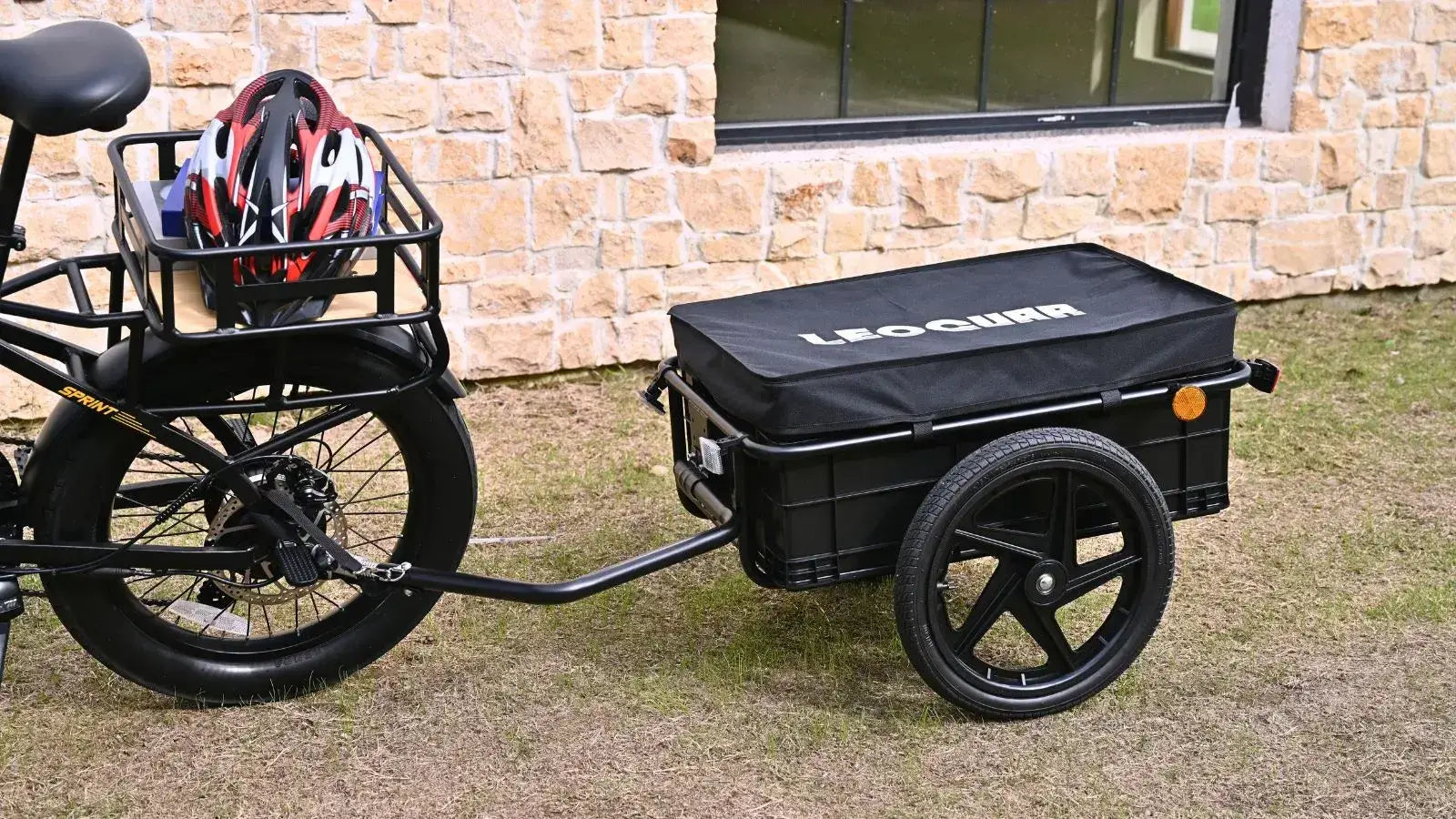

Choosing The Right Bike

A big mistake is thinking any regular e-bike can handle commercial delivery work. A delivery vehicle is a tool, not a toy. It works 8-10 hours a day, carries heavy loads, and must be very reliable. A purpose-built electric delivery bike is made specifically for this demanding environment. Buying the right equipment from the start prevents costly breakdowns and safety problems.

Cargo and Durability

The main difference is in the frame and cargo abilities. Standard e-bikes are built for one rider and minimal gear. A true electric delivery bike, often called an e-cargo bike, is built differently.

Frame Construction: Look for frames made from high-grade aluminum or steel, with reinforced welds and a low center of gravity for stability under load. The frame must be rated for a high total payload capacity (often over 400 lbs / 180 kg).

Built-in Racks: Purpose-built models have built-in, frame-mounted front and rear racks. Unlike bolt-on accessories, these are part of the bike's structure, so they can safely handle heavy, bulky items without hurting handling. There are many different types of e-cargo bikes, from longtails with extended rear racks to front-loading bakfiets style bikes.

The Power Trio

The performance and reliability of an electric delivery bike depend on how well its three core electrical parts work together: the battery, motor, and brakes.

Battery: All-day range is essential. This means a high-capacity battery (600Wh or more) is needed. For serious commercial use, systems with dual-battery capacity or swappable batteries are the best choice. This lets a rider swap a dead battery for a fresh one in seconds, removing charging downtime during a shift.

Motor: The choice is usually between a hub-drive (motor in the wheel) and a mid-drive (motor at the pedals). While hub drives often cost less, a high-quality torque-sensing mid-drive motor provides a more natural, responsive ride and better hill-climbing ability when carrying heavy loads. Power output (measured in watts) and torque (measured in Newton-meters) are key numbers for performance under load.

Brakes: This is a critical safety feature. Mechanical disc brakes work for some bikes, but for a heavy cargo bike, hydraulic disc brakes are essential. They provide much more stopping power and require less hand pressure, reducing rider fatigue and ensuring the ability to stop safely in all weather.

Safety and Compliance

Running a commercial fleet, no matter the size, requires focus on safety and legal compliance. This protects your riders, your business, and the public.

Certified Batteries: Battery fires are a serious and well-documented danger with cheap, uncertified lithium-ion batteries. You must only buy and use e-bikes with UL-certified batteries (specifically UL 2849 for the e-bike system and UL 2271 for the battery itself). This certification means the battery has passed rigorous third-party safety testing. Programs like NYC's e-bike trade-in program exist specifically to get dangerous, uncertified batteries off the streets.

Local Rules: E-bike laws vary by city and state. Operators must understand and follow local rules about speed limits (e.g., Class 1, 2, or 3 e-bikes), age restrictions, and required equipment like lights, bells, and reflectors. Following these rules is not just about avoiding tickets - it is about being a responsible community member.

Real-World Implementation

The benefits of the electric delivery bike are proven daily on the streets of the world's busiest cities. From global shipping companies to local restaurants, businesses are successfully adding these vehicles to their operations. However, success requires more than just buying a bike - it needs a thoughtful approach to integration, workflow, and addressing practical challenges.

Logistics Giants Case Study

Large-scale adoption by industry leaders provides the ultimate proof of concept. These companies have billions of dollars and their reputations at stake, and their decisions are based on hard data. The fact that they are turning to e-bikes for city delivery is a powerful endorsement.

For example, we can see how major players like Amazon are using e-bikes and micro-mobility hubs in dense areas like New York City. They use custom-built electric cargo bikes to navigate crowded streets more efficiently than their famous vans. This multi-modal approach lets them use large vehicles for main routes to a central city hub, then deploy agile e-bike fleets for the final, most challenging delivery stage. This model increases delivery speed, reduces emissions, and cuts operating costs in their most expensive markets.

A Rider's Typical Day

To understand the practical impact, consider the daily workflow of a courier.

A rider starts their shift not by driving around looking for van parking, but by grabbing a fully charged, swappable battery from a charging station. Their first set of packages goes onto the bike's built-in racks. During the morning rush, they use dedicated bike lanes to bypass traffic jams. Each stop takes only a minute or two, as they can pull right up to the building's entrance. There is no double-parking, no feeding a meter. They can access courtyards and pedestrian areas that a van could never reach. By midday, they have completed more deliveries than a driver on a similar route and are back at the hub for their next wave of packages, swapping their battery in under 30 seconds.

This workflow is naturally more efficient, less stressful for the rider, and provides a better customer experience with faster, more precise delivery times.

Overcoming Common Hurdles

Moving to an e-bike fleet has its challenges. Planning ahead can reduce these problems.

Theft and Security: High-value e-bikes are targets for theft. A strong security plan is essential. This includes buying high-quality, hardened steel U-locks and heavy-duty chains, training riders on proper locking techniques (frame to a fixed object), and using GPS tracking devices hidden within the bike's frame.

Weather Conditions: Rain, snow, and extreme cold can impact both rider comfort and battery performance. Giving riders high-quality waterproof gear is a must. For the bikes, make sure they have fenders, strong lights, and tires appropriate for the climate. Battery performance can decrease in cold weather, so planning for slightly shorter ranges or more frequent battery swaps during winter months is a wise adjustment.

Maintenance and Downtime: While maintenance is lower, it is not zero. A flat tire or broken brake line can take a vehicle out of service. For fleet operators, having a maintenance plan is critical. This could involve an in-house mechanic, a service contract with a local bike shop, and keeping common replacement parts (tires, tubes, brake pads) on hand to minimize downtime.

Strategic Fleet Integration

Successfully using an electric delivery bike fleet requires strategic thinking. It is about building a system, not just buying equipment. This system should be scalable, data-informed, and centered on rider safety and efficiency.

Scaling Your Fleet

Starting small is a smart approach. Begin with a pilot program of one to five bikes on a specific, high-density route. This lets the business test workflows, gather real-world performance data, and identify unexpected challenges in a controlled environment.

Once the model is proven, scaling can happen. A key consideration for growth is the charging and battery management setup. For a large fleet, a dedicated area with multi-bay chargers for swappable batteries is far more efficient than plugging in each individual bike. This ensures a constant supply of fresh batteries and keeps the fleet on the road.

Data and Management

Modern delivery operations run on data. An electric delivery bike fleet should be no different.

GPS Tracking: This is essential for more than just theft prevention. GPS data provides real-time visibility of your fleet, allows for dynamic route optimization, and helps verify delivery times and locations.

Fleet Management Software: Technology can track key numbers like mileage, battery health, and service intervals. This data helps predict maintenance needs, identifies underperforming vehicles or routes, and provides the analytics needed to justify further investment and expansion. It transforms fleet management from reactive to proactive.

Rider Training Protocols

The rider is the most important part of the system. Proper training is a necessary investment in safety and efficiency. A complete training program should cover:

Vehicle Operation: Proper use of pedal-assist levels, gear shifting (if applicable), and understanding the bike's range and load limits.

Advanced Urban Cycling Skills: Defensive riding techniques, navigating bike lanes, interacting with pedestrians and vehicle traffic, and proper signaling.

Cargo Management: Best practices for securing loads of different shapes and sizes to ensure stability and safety.

Emergency Procedures: What to do in case of a flat tire, a dead battery, or an accident.

A well-trained rider is a safer, faster, and more confident operator, directly increasing the value of the entire fleet.

The Future is Electric

The evidence is clear and strong. For businesses and individuals involved in city shipping, the electric delivery bike is no longer a niche novelty but a strategic necessity. It offers an unmatched solution to the ongoing challenges of last-mile delivery: reducing operating costs, meeting sustainability goals, and navigating crowded cityscapes with unmatched agility.

By understanding the key features of a purpose-built vehicle, analyzing the powerful unit economics, and implementing a strategic approach to fleet management and rider training, any delivery operation can use this technology. The quiet revolution is already happening on our city streets. The question is no longer if electric delivery bikes will reshape urban commerce, but how quickly your organization will adapt to embrace the future.

Frequently Asked Questions

Q: How long does an electric delivery bike battery last during a typical workday?

A: A high-quality electric delivery bike with a 600Wh+ battery typically lasts 6-8 hours of continuous delivery work, covering 40-60 miles depending on terrain, load weight, and assist level used. Many commercial operations use swappable battery systems to eliminate downtime during shifts.

Q: What is the maximum weight capacity for cargo on an electric delivery bike?

A: Purpose-built electric cargo bikes can typically carry 200-400 pounds of cargo, with some heavy-duty models handling up to 500 pounds. The total payload capacity includes both the rider and cargo weight, so always check the manufacturer's specifications for your specific model.

Q: Are electric delivery bikes safe to ride in traffic alongside cars and trucks?

A: Yes, when operated by properly trained riders following safety protocols. Electric delivery bikes should have hydraulic disc brakes, bright LED lights, and reflective materials. Riders need training in defensive cycling techniques, proper use of bike lanes, and urban traffic navigation to ensure safe operation.

Q: How much can a business save per year by switching from delivery vans to electric bikes?

A: Based on typical operating costs, a business can save approximately $6,550 per vehicle per year when switching from a small delivery van to an electric cargo bike. This includes savings on fuel, maintenance, insurance, and parking costs. The exact savings depend on local fuel prices, parking fees, and usage patterns.

Q: What maintenance is required for electric delivery bikes compared to gas vehicles?

A: Electric delivery bikes require significantly less maintenance than gas vehicles. Regular maintenance includes checking tire pressure, brake pad replacement, chain lubrication, and battery care. There are no oil changes, spark plug replacements, or exhaust system repairs. Most operators spend about $300 annually on maintenance compared to $1,500+ for gas vehicles.

Leave a comment