Bike Brakes Evolution: How Ebike Hydraulic Brakes Match Speed

Introduction: The Need for Speed… and to Stop

Picture the thrill: the instant, silent surge of an e-bike's motor kicking in, pushing you forward with an ease that regular cycling can't match. It's an exciting feeling of power and speed. Now, picture the immediate, urgent need to stop as a car pulls out unexpectedly. In that critical moment, the exciting speed becomes a massive amount of momentum that you need to control. This is the core problem that drove a revolution in bike brake technology.

When e-bikes first appeared, they brought with them two game-changing factors: higher speeds and increased weight. The existing braking systems, designed for lightweight, human-powered bicycles, were suddenly and dangerously outmatched. The evolution of e-bike brakes wasn't just about small improvements; it was a complete redesign born from necessity. We're about to journey through that evolution, from overwhelmed rim brakes to the advanced hydraulic systems that now define e-bike safety and performance.

Early Days: Old Solutions, New Problems

Before e-bikes changed the landscape, the world of bicycle braking was relatively simple. The existing technologies were lightweight and cost-effective, perfectly suited for the machines they were designed to stop. However, when manufacturers began putting these traditional systems onto the first generation of heavier, faster e-bikes, their weaknesses were dangerously exposed. It was an attempt to apply old, familiar solutions to a brand-new, high-stakes problem, and the results were simply not good enough.

Rim Brakes: A Heavy Burden

The most common system was the rim brake. Its mechanics are beautifully simple: pulling the brake lever causes two pads to squeeze against the wheel's rim, creating friction to slow the bike down. For decades, this was the standard for road and commuter bikes.

Pros for Traditional Bikes:

- Extremely lightweight.

- Simple to maintain and adjust.

- Inexpensive to manufacture and replace.

Critical Failures on E-bikes:

- Poor All-Weather Performance: In wet or muddy conditions, the rim becomes slick, drastically reducing braking power and creating a terrifying lack of response.

- Insufficient Force: The sheer momentum of a 50-70 lb e-bike traveling at 20-28 mph overwhelmed the clamping force rim brakes could generate. This led to longer, less predictable stopping distances.

- Accelerated Rim Wear: The increased force and frequency of braking on an e-bike literally wore down the structural surface of the wheel rim itself, eventually requiring a full wheel replacement.

The Tipping Point: Why Disc Brakes Became Non-Negotiable

The shortcomings of rim brakes on e-bikes created a clear and urgent need for a better solution. The answer didn't come from improving the old system, but from adopting a technology that was already proving its worth in the demanding world of mountain biking: the disc brake. This wasn't just an upgrade; it was a fundamental change in brake design that permanently altered the course of e-bike development and safety. Today, disc brakes are not just an option but the expected standard, commanding over 70% of the new bike market and an even higher percentage in the e-bike segment.

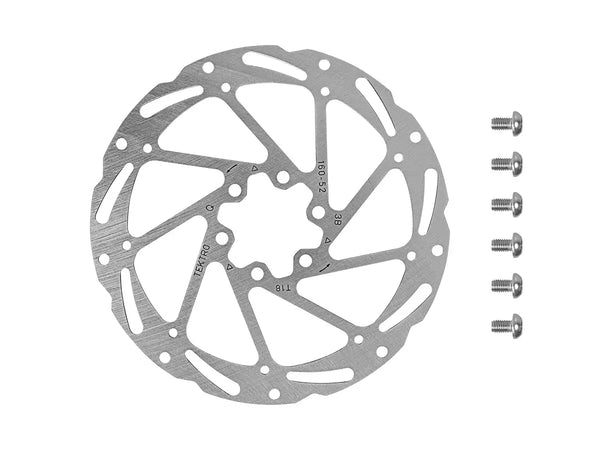

A Paradigm Shift to the Hub

The core genius of the disc brake is moving the braking surface away from the vulnerable wheel rim to a dedicated, smaller disc—or rotor—mounted at the center of the wheel hub. A device called a caliper, which holds the brake pads, is mounted to the bike's frame or fork. When you pull the brake lever, the caliper squeezes the pads onto this rotor. This single change solved the biggest problems of rim brakes instantly. Because the rotor is at the hub, it is far less affected by water, mud, or the minor wobbles of a wheel that isn't perfectly true. The result is powerful, consistent, and reliable braking in virtually any condition.

Mechanical Disc Brakes: A Step Forward

The first widely adopted disc brakes were mechanical. These systems operate using a familiar principle: a standard steel brake cable connects the brake lever to the caliper. When you pull the lever, it pulls the cable, which in turn actuates a lever on the caliper to force the pads against the rotor.

This was a massive improvement over rim brakes, offering far superior stopping power and all-weather reliability. However, for the specific demands of e-bikes, they still had drawbacks. The primary issue is cable stretch. Over time, the steel cable can stretch slightly, leading to a "spongy" or delayed feeling at the lever. This also means they require frequent manual adjustment to compensate for pad wear and maintain a crisp lever feel. Furthermore, they still require significant hand force on long descents, which can lead to rider fatigue.

The Gold Standard: The Rise of Hydraulic Brakes

While mechanical disc brakes were a crucial stepping stone, the true solution for modern e-bikes arrived with hydraulic systems. By replacing the fallible steel cable with a sealed system of incompressible fluid, ebike hydraulic brakes unlocked a new level of power, control, and reliability. This technology is the current gold standard, providing the performance necessary to safely manage the speed and weight of today's most advanced electric bikes. It's the difference between simply stopping and stopping with absolute confidence and precision.

The Power of Fluid

Hydraulic bike brakes operate on a simple but powerful physics principle known as Pascal's Law. Instead of a cable, a sealed hose filled with a special hydraulic fluid (either mineral oil or DOT fluid) connects the brake lever to the caliper. The brake lever assembly is actually a master cylinder containing a piston. When you squeeze the lever, this piston pushes fluid through the hose. Because the fluid is incompressible, that force is transferred perfectly to larger pistons inside the caliper at the wheel. These caliper pistons then drive the brake pads against the rotor. This system acts as a force multiplier, meaning a light squeeze at the lever generates immense clamping force at the wheel, something a mechanical cable could never achieve.

Key Hydraulic Components

Understanding the system helps appreciate its effectiveness:

- Master Cylinder (Lever): Houses the lever blade and the primary piston that initiates the fluid pressure.

- Sealed Hose: A durable, inflexible line that transfers the fluid and pressure without loss.

- Hydraulic Fluid: The lifeblood of the system. The two main types are DOT fluid (common in the automotive industry) and mineral oil (popularized by brands like Shimano). They are not interchangeable.

- Caliper: The mechanism at the wheel that holds the caliper pistons and brake pads.

- Pistons: Located inside the caliper, these are what the fluid pushes against to move the brake pads.

Tangible Rider Benefits

For an e-bike rider, the switch to a hydraulic system provides immediate, noticeable advantages. The first is superior modulation. This is the ability to finely control the amount of braking power, from a light drag to a full, locked-wheel stop, all with minimal changes in finger pressure. This gives you more nuanced control on loose surfaces or in tight situations.

The second is a massive increase in raw stopping power with significantly less hand fatigue. The force multiplication effect means you can control a heavy e-bike on a steep descent with just one or two fingers, preserving your grip and reducing arm pump. Finally, hydraulic systems are self-adjusting. As the brake pads wear down, the pistons naturally sit slightly further out to maintain the same distance from the rotor, ensuring a consistent lever feel until the pads need replacement.

E-Bike Specific Innovations

As e-bikes became more specialized, so did their braking systems. It was no longer enough to just use a standard hydraulic disc brake. Engineers began tailoring components specifically for the unique forces generated by heavy cargo e-bikes, high-speed commuters, and powerful electric mountain bikes (e-MTBs). These e-bike specific features are what truly separate a general-purpose brake from a dedicated e-bike safety system.

Larger Rotors for Heat

One of the simplest and most effective e-bike upgrades is a larger rotor. While a standard bike might use 140mm or 160mm rotors, it's common to see e-bikes equipped with 180mm or even 203mm rotors. A larger diameter rotor provides two key benefits. First, it offers more mechanical leverage, meaning the caliper has to do less work to produce the same amount of stopping torque. This translates to more power. Second, and more importantly for e-bikes, a larger rotor has more surface area, allowing it to dissipate heat more effectively. On a long, steep descent, a heavy e-bike can generate tremendous heat in the brakes, which can lead to a phenomenon called "brake fade," where the system becomes less effective. Larger rotors are essential for preventing this.

More Pistons, More Power

Looking closely at a brake caliper, you'll see the circular pistons that push the pads. Most standard bike brakes use a 2-piston design (one on each side). However, for high-performance e-bikes, 4-piston calipers are becoming the norm. A 4-piston caliper has two pistons of differing sizes on each side. This design not only increases the total surface area pushing on the back of the brake pad—creating more clamping force—but it also allows for better modulation and more even pad wear. For a heavy e-MTB or a fully loaded cargo e-bike, the immense power of a 4-piston brake is a non-negotiable safety feature.

The Smart Connection: Cut-Off Sensors

A feature found almost exclusively on e-bikes is the motor cut-off sensor, or inhibitor. This is a small electronic switch integrated into the brake lever assembly. As soon as you begin to pull a brake lever, even slightly, it sends a signal to the bike's controller to instantly cut power to the motor. This is a critical safety feature that ensures you are never braking while the motor is still trying to accelerate, preventing conflicting forces and guaranteeing that 100% of your effort goes toward stopping the bike.

Essential Brake Maintenance

Even the most advanced hydraulic bike brakes require basic care to perform at their peak. As the single most important safety system on your e-bike, your brakes deserve consistent attention. Fortunately, keeping them in top condition is straightforward. Integrating a few simple checks into your routine will ensure you have reliable stopping power on every single ride.

Your Pre-Ride Safety Check

Before every ride, perform a quick 30-second check. Squeeze both brake levers firmly. They should feel solid and consistent, not "spongy" or soft. The lever should stop well before it touches the handlebar. Next, perform a quick visual inspection. Look at the brake pads within the caliper. You should be able to see a decent amount of pad material (typically more than 1mm). Finally, glance at the rotors to ensure they are clean and straight, not bent or discolored.

Keeping Brakes Contaminant-Free

The effectiveness of disc brakes relies on the pure friction between the pad and the rotor. Any form of lubricant, oil, or grease that gets on these surfaces will ruin their performance, often causing a loud squeal and a severe loss of power. Be extremely careful when lubricating your chain to avoid overspray. If you suspect your rotors are contaminated, you can clean them thoroughly with a clean rag and a high-purity isopropyl alcohol. If the pads themselves are contaminated, they almost always need to be replaced.

When to Seek a Pro

While daily checks are easy, some tasks are best left to a professional bike mechanic. The most common is a "brake bleed." If your brake levers feel spongy or you have to pull them further than usual, it's a sign that air has entered the hydraulic lines. A brake bleed is the process of purging this air and replacing old fluid. We recommend having this service done annually, or whenever you notice a decline in performance. A mechanic should also be consulted for replacing pads and rotors if you are not comfortable doing so yourself, as proper installation is critical for safety.

The Future of Stopping

The journey of the e-bike brake is a clear story of technology rising to meet a challenge. We've moved from the inadequate grip of rim brakes, through the transitional phase of mechanical discs, to the current gold standard of powerful, e-bike specific hydraulic systems. This evolution was driven not by a desire for novelty, but by the fundamental requirements of physics.

Modern ebike hydraulic brakes, with their large rotors, multi-piston calipers, and integrated motor inhibitors, are more than just components. They are complete, engineered safety systems designed to give you the control and confidence needed to fully enjoy the speed and freedom your e-bike offers. Investing in a quality braking system—and maintaining it—is the most important decision you can make for your safety on the road or trail.

Frequently Asked Questions

1. Q: How often should I replace my e-bike brake pads?

A: Brake pad replacement depends on your riding style, terrain, and weather conditions. Generally, you should inspect your pads every few weeks and replace them when the material is worn down to 1mm or less. Heavy e-bike riders or those who frequently ride in hilly areas may need to replace pads every 6-12 months, while casual riders might go 1-2 years between replacements.

2. Q: Can I upgrade my mechanical disc brakes to hydraulic brakes on my existing e-bike?

A: Yes, in most cases you can upgrade from mechanical to hydraulic disc brakes. However, this typically requires replacing the brake levers, calipers, and adding hydraulic hoses. The brake rotors can usually be kept if they're in good condition. This upgrade significantly improves braking power and feel, making it a popular modification for e-bike owners.

3. Q: Why do my e-bike brakes squeal, and how can I fix it?

A: Brake squealing is usually caused by contamination on the rotor or pads, glazed brake pads, or misaligned components. First, clean your rotors with isopropyl alcohol and check for oil contamination. If the pads are glazed (shiny surface), lightly sand them with fine sandpaper. Ensure your caliper is properly aligned with the rotor. If squealing persists, the pads may need replacement.

4. Q: What's the difference between DOT fluid and mineral oil in hydraulic brakes?

A: DOT fluid and mineral oil are two different types of hydraulic brake fluid that are not interchangeable. DOT fluid (used by brands like SRAM and Avid) is hygroscopic, meaning it absorbs moisture over time and needs more frequent replacement. Mineral oil (used by Shimano and Magura) doesn't absorb moisture but can be more sensitive to temperature changes. Always use the fluid specified by your brake manufacturer.

5. Q: How do I know if my hydraulic brakes need bleeding?

A: Your hydraulic brakes need bleeding if the lever feels spongy or soft when squeezed, if you have to pull the lever closer to the handlebar than usual to engage the brakes, or if braking power has noticeably decreased. These symptoms indicate air has entered the hydraulic system. A properly bled brake should have a firm, consistent lever feel with good stopping power.

Leave a comment