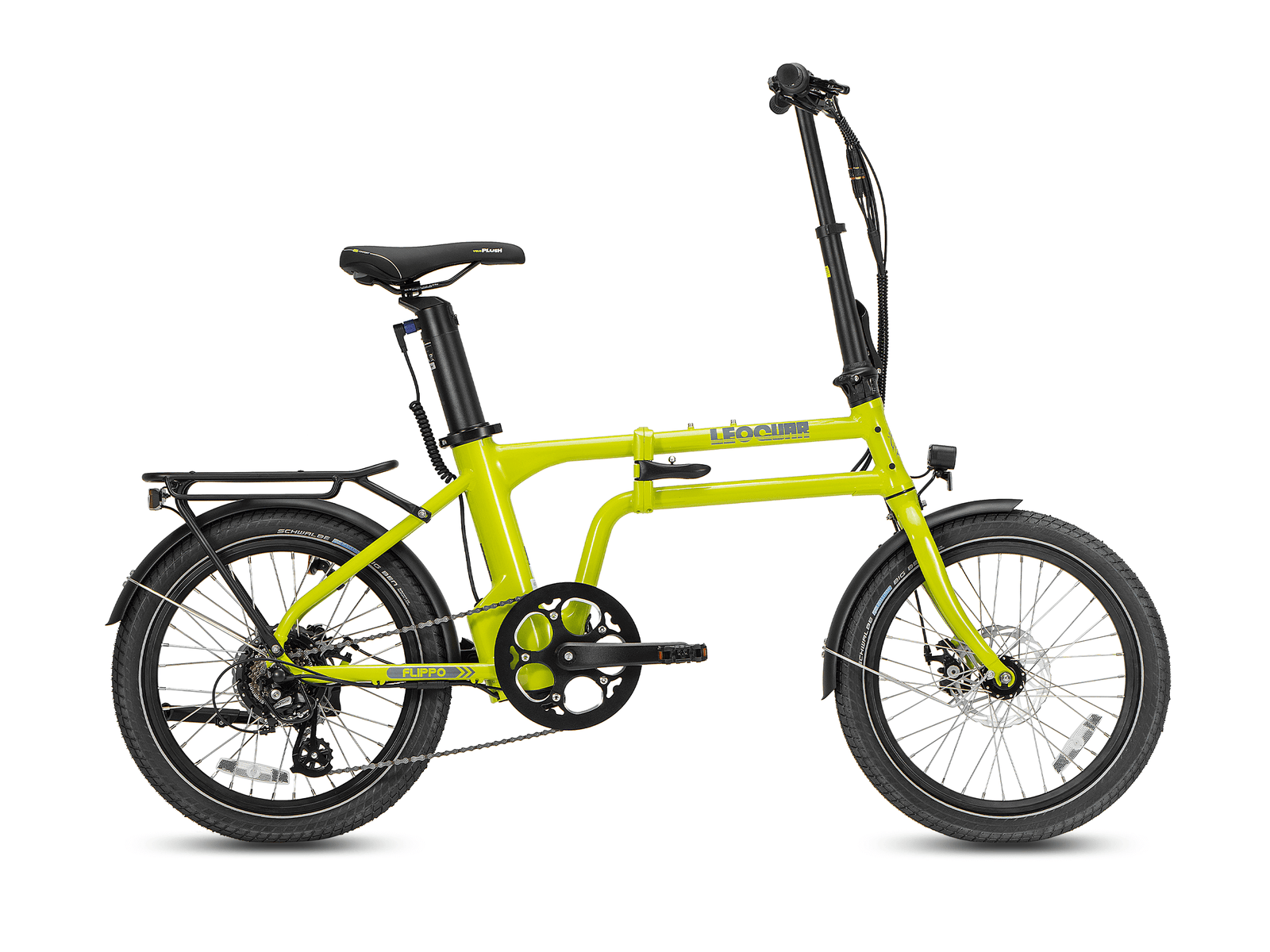

Do Electric Bike Frames Have Hollow Interiors? Here's the Truth

Electric bike frames commonly feature hollow interiors. This frame construction choice is crucial for their performance and efficiency, and it plays a major role in effective bike design. Hollow frames reduce weight while maintaining strength, providing the ideal balance needed for reliable and agile electric bikes. They also allow for sleek and modern designs, showcasing how thoughtful bike design and smart frame construction together enhance both aesthetics and functionality. Understanding this aspect helps buyers make informed decisions about e-bikes.

In this article, we will explore the materials used in electric bike frame construction, the benefits of hollow interiors, and future trends in electric bike design.

Understanding Electric Bike Frame Materials

Electric bike frames can be crafted from various materials, each offering distinct advantages that influence overall bike design. The most common materials include aluminum, carbon fiber, and other composites. These materials contribute significantly to the bike's weight, strength, and durability, shaping both performance and aesthetic aspects of modern bike design.

Aluminum Frames

Aluminum is one of the most popular materials for electric bike frames design. Known for its lightweight and strong properties, aluminum frames provide excellent support while keeping the bike relatively light. Aluminum electric bike frames often feature hollow interiors, a key element of frame construction that enhances the bike's lightweight nature without compromising strength. This balance makes aluminum a preferred choice for many e-bike manufacturers.

Carbon Fiber Frames

Carbon fiber is another popular material used in high-end electric bike frame construction. It's renowned for its exceptional strength-to-weight ratio, making it an excellent choice for performance-oriented bikes. Carbon fiber electric bike frames design are typically hollow, a characteristic resulting from the composite fabrication process. This type of frame construction allows for complex shapes, improving both aerodynamics and the sleekness of modern bike design.

Composite Fabrication

Composite materials, which may include carbon fiber, are often used in electric bike frames. These materials are engineered to be both lightweight and robust. The composite fabrication process frequently involves creating hollow sections to maximize strength while minimizing weight. This strategic approach to frame construction is a key factor in boosting both the efficiency and durability of electric bikes, further advancing modern bike design.

Why Hollow Interiors?

The concept of hollow interiors in electric bike frames may seem unusual at first glance, but it serves several important purposes:

- Weight Reduction: One of the primary reasons for adopting Hollow Interiors is to reduce the bikes overall weight. A lighter bike is easier to handle, accelerates more quickly, and consumes less energy from the motor, enhancing the bike's efficiency. By strategically designing Hollow Interiors, manufacturers achieve a perfect balance between lightness and strength.

- Structural Strength: Despite using less material, electric bike frames construction with Hollow Interiors can provide impressive structural strength. This method plays a key role in modern bike design, where achieving both durability and lightness is essential. The circular shape of hollow tubes distributes stress evenly across the frame, offering excellent durability without the need for solid materials. Thanks to this smart approach to frame construction, electric bikes can maintain high levels of resilience while remaining lightweight and agile, aligning perfectly with the goals of efficient bike design.

- Cost-Effectiveness: By using less material during frame construction, manufacturers can lower production costs. These savings can then be passed on to consumers, making high-quality electric bikes with innovative Hollow Interiors more accessible to a broader market.

- Aesthetic Appeal: Beyond function, Hollow Interiors contribute to sleek and modern electric bike designs. Advanced frame construction techniques allow materials to be molded into aerodynamic shapes, creating a stylish look that appeals to today’s riders. In a competitive market, the visual and functional benefits of Hollow Interiors provide a clear edge.

Electric Bike Design Considerations

When crafting electric bikes, manufacturers focus on multiple aspects of bike design to ensure optimal performance and user experience. Here are some critical design considerations:

Aerodynamics

The aerodynamic aspect of bike design is crucial for reducing air resistance and increasing speed. Hollow frames allow for more streamlined shapes, improving both the bike’s aerodynamics and overall efficiency without adding unnecessary weight.

Battery and Motor Integration

Electric bikes need to accommodate batteries and motors without compromising the frame's structural integrity. The hollow interior of the frame plays a vital role in bike design, providing space for seamless integration of these components while maintaining a clean and sleek appearance.

Durability and Longevity

Durability is a top priority in bike design for electric bike manufacturers. The materials and frame construction techniques used in hollow frames are carefully selected to withstand the rigors of daily use, ensuring that the bike remains reliable and sturdy over time. Strong electric bike frame construction is essential for maintaining performance and extending the bike’s usable lifespan.

Comfort and Ride Quality

A lightweight frame plays a significant role in enhancing comfort, which is a key consideration in modern bike design. Electric bike frames with hollow interiors are typically better at absorbing shocks and vibrations, providing a smoother and more enjoyable riding experience.

The Future of Electric Bike Frame Design

As technology advances, the design and frame construction of lightweight electric bike frames will continue to evolve. Innovations in composite fabrication and material science may lead to even lighter and stronger frame construction methods, enhancing the performance and appeal of electric bikes.

Sustainability and Eco-Friendliness

The push toward sustainable transportation solutions is heavily influencing frame construction and bike design for electric bikes. Manufacturers are exploring eco-friendly materials and production processes to minimize environmental impact. The use of recyclable materials and energy-efficient manufacturing techniques is likely to become more prevalent as sustainability becomes a core part of modern bike design strategies.

Customization and Personalization

As consumer demand for personalized products grows, electric bike manufacturers may offer more customization options. This could include bespoke frame designs and the ability to choose specific materials or finishes, allowing riders to tailor their bikes to their preferences.

Leave a comment