Can You Install an Ebike Motor on Any Frame? Compatibility Tips

Introduction

People now want to add electricity to their bicycles more than ever. DIY ebike conversion kits give you a way to do this. These kits often cost less than buying a new electric bike.

Many cyclists like the idea of customizing their own bikes. This leads to an important question: Can you install an ebike motor on any bike frame? The simple answer is not exactly any frame, but many bicycles can be converted if you check some key factors carefully. It's less about a clear "yes" and more about "yes, if certain conditions are met."

This guide will help you understand if your bike frame can work with an ebike motor. We'll look at what you need to check before starting your conversion project.

The Quick Answer: Is Your Bike Frame a Candidate for an Ebike Motor?

While it would be nice to put an ebike motor on any bicycle, reality is more complicated. Most standard bike frames with common designs and strong construction can take an ebike motor. The word "any" is too broad, though.

We need to first look at the two main types of ebike motors: hub motors (in the front or rear wheel) and mid-drive motors (at the bottom bracket). They attach differently to bikes and have different requirements. This is one of the most important compatibility issues.

The frame material (like steel, aluminum, or carbon fiber), its shape, and its condition are all critical factors. You need to check all these things carefully for a safe and working conversion.

Why Frame Compatibility is Paramount for a Safe and Successful Ebike Conversion

Understanding why frame compatibility matters is key. Adding an ebike motor means adding a system of new parts. This includes the motor, a battery (often the heaviest part, usually 5-10 pounds), a controller, a display, and wiring.

These additions put new forces and stress on the bicycle frame. The motor puts torque directly on the frame - at the dropouts for hub motors or the bottom bracket for mid-drive motors. Common ebike motors range from 250W for basic pedal-assist to powerful 750W+ units that give strong acceleration and hill-climbing ability.

The extra weight, usually adding 15-25 pounds or more, affects how the bike handles and puts constant stress on the frame. Higher potential speeds also demand more from the frame's strength and from components like brakes.

Ignoring these factors creates serious safety risks. A frame that isn't compatible or is weakened can fail under pressure, causing damage to parts, loss of control, and possible injury to the rider. Making sure your frame can safely handle these new demands is essential for a successful ebike motor conversion.

Understanding Ebike Motor Types and Their Specific Frame Demands

Your choice of ebike motor type determines what your frame needs. Let's explore the common options.

Hub Motors (Front and Rear):

Hub motors put the motor right into the wheel hub. The wheel's axle is the motor's axle. They're usually easier to install than mid-drives.

Frame Requirements for Hub Motors:

Dropout Spacing (Over Locknut Dimension - OLD): This is the width between the frame's dropouts where the wheel axle fits. This measurement is critical. Front hubs are usually 100mm, while rear hubs are often 135mm for quick-release setups. Modern mountain bikes use 110mm front and 148mm rear, typically with thru-axles. Measure this carefully with calipers.

Axle Type: Most hub motor kits work with standard quick-release dropouts. Options for thru-axle frames are growing but less common in DIY kits. The motor's axle must fit tightly in the dropout slot.

Dropout Material & Design: Steel dropouts are strongest and most forgiving. Aluminum dropouts are common but need more care; they should be thick and strong enough, as aluminum gets tired more easily. Carbon fiber dropouts have special challenges (more on this later). The dropouts need flat, parallel surfaces for the motor axle and torque arm washers to fit securely. Vertical dropouts are normal; horizontal dropouts can work but need careful adjustment.

Torque Arms: These are essential for almost all hub motor installations, especially with aluminum or carbon frames, or any motor over 250W. A hub motor creates rotational force that tries to spin the axle in the dropouts. Torque arms brace against the frame or fork to prevent this, protecting the dropouts from damage.

Fork Compatibility (for front hub motors): The fork material matters; some lightweight carbon forks aren't suitable due to stress. Steel or strong aluminum forks are better. The fork shape must allow space for the motor. Small retention tabs on fork dropouts may need filing down for the motor axle to fit fully.

| Dropout Standard | Typical OLD | Common Axle Type | Hub Motor Kit Suitability Notes |

| Front Standard QR | 100mm | Quick Release (9mm) | Most front hub motor kits are designed for this. |

| Rear Standard QR | 135mm | Quick Release (10mm) | Most rear hub motor kits target this standard. |

| Rear Road/CX (older) | 130mm | Quick Release (10mm) | May require slight frame spreading (steel) or specific narrower hub. |

| Front Boost | 110mm | Thru-Axle (15mm) | Fewer kits available; requires specific thru-axle compatible motor. |

| Rear Boost | 148mm | Thru-Axle (12mm) | Fewer kits available; requires specific thru-axle compatible motor. |

| Rear Super Boost | 157mm | Thru-Axle (12mm) | Very few kits; highly specialized. |

| Fat Bike Front | 135mm/150mm | QR or Thru-Axle | Specific fat bike hub motors required. |

| Fat Bike Rear | 170mm/177mm/190mm/197mm | QR or Thru-Axle | Specific fat bike hub motors required. |

Mid-Drive Motors:

Mid-drive motors attach at the bike's bottom bracket area, replacing the crankset. They power the chain directly, using the bike's gears. This gives better weight distribution and efficient power delivery through the gears.

Frame Requirements for Mid-Drive Motors:

Bottom Bracket Shell Type & Width: This is often the biggest compatibility issue for mid-drives. Most DIY mid-drive kits (like Bafang BBS02/BBSHD) work with BSA/English threaded bottom bracket shells, typically 68mm or 73mm wide (standard for most mountain and hybrid bikes). Fat bikes might have 100mm or 120mm BSA shells, needing specific wider mid-drive versions. PressFit BB standards (like BB86/92, BB30, PF30), where bearings press directly into the frame, generally don't work directly without special adapters, which can cause their own problems (noise, alignment).

Clearance: You need enough open space around the BB shell for the motor housing. This includes room from the chainstays (especially on the drive side), the downtube, and the seat tube. The motor unit has a physical size that must fit without touching these frame parts.

Frame Geometry: Some unusual frame designs, especially certain full-suspension systems or bikes with oddly shaped tubes around the BB area, can physically block a mid-drive motor.

Specific Mounts: Some modern ebike frames are designed with built-in mounting points for specific motor systems (e.g., Shimano STEPS, Bosch, Brose). Standard DIY conversion kits typically aren't designed to fit these proprietary mounts and would need extensive custom work.

Briefly Mention Other/Niche Types:

Friction drive motors, which press a roller against the tire, are less common. They're often easier to fit since they don't connect directly with dropouts or BB shells, but they can be less efficient, especially in wet conditions, and may wear out tires.

Your Bike MOT: A Comprehensive Frame Assessment Checklist Before Conversion

Before committing to an ebike motor conversion, check your bike frame thoroughly. Think of this as a Make-Or-Torque (MOT) test for your future ebike. This checklist will help you evaluate the key aspects.

-

Frame Material Deep Dive:

The material your frame is made from greatly affects its suitability and the precautions needed.

-

Steel:

-

Pros: Very durable, excellent fatigue life, forgiving of small imperfections. Steel can often be "cold set" (carefully bent) to slightly adjust dropout spacing for hub motors (e.g., spreading a 130mm rear to 135mm). It's generally easy to work with for minor modifications like filing dropouts if needed.

-

Cons: Can be heavier than other materials, though modern steel alloys offer good strength-to-weight ratios.

-

-

Aluminum (Alloy):

-

Pros: Lightweight, stiff, and very common in modern bicycles. Good resistance to rust.

-

Cons: Less forgiving of bending or over-stressing than steel; trying to spread aluminum dropouts is generally not recommended as it can lead to cracking. Aluminum has a limited fatigue life, so older, heavily used aluminum frames should be checked very carefully. Be especially cautious with very lightweight, thin-walled aluminum race frames.

-

-

Carbon Fiber: This material needs special attention for DIY ebike conversions.

-

Common Advice: Often discouraged due to several risks. Clamping forces from motor mounts or battery brackets can crush carbon tubes if over-tightened or poorly distributed. Carbon doesn't yield or bend like metal; it can fail completely if stressed beyond its limits. Checking internal damage in carbon frames without special equipment is difficult.

-

Nuance & Expert Insight: Some in the ebike community suggest that conversions can be done on carbon frames, particularly with hub motors. The key conditions are: using strong, correctly installed torque arms to transfer all motor torque to the frame structure (not just the dropouts), and ensuring any clamping forces for batteries or controllers are widely distributed and not over-tightened. Mid-drive motors are generally considered riskier on carbon frames due to the complex stresses at the bottom bracket shell, which is often a highly engineered and critical part of a carbon frame.

-

Emphasize Risks: Converting a carbon frame will almost certainly void any manufacturer's warranty. A mistake can lead to irreparable frame damage and a dangerous failure. If considering a carbon frame conversion, extreme caution is essential. We strongly recommend professional consultation or choosing a more suitable frame material if you don't have deep experience with carbon.

-

-

Titanium:

-

Pros: Excellent strength-to-weight ratio, highly rust-resistant, superb ride quality.

-

Cons: Expensive and less common, making them rarer candidates for DIY conversions. Modifying titanium is also more challenging.

-

When comparing materials simply for ebike motor suitability, steel offers the best 'ductility' (ability to bend without breaking) making it forgiving. Aluminum is stiffer but more 'brittle' under extreme stress. Carbon fiber is exceptionally strong for its weight in intended directions but can be vulnerable to impacts and unusual loads.

-

Frame Type and Geometry Considerations:

Different bike styles present unique compatibility challenges and advantages.

-

Mountain Bikes (Hardtail): Often excellent candidates. Their frames are typically built to be tough enough for off-road use. They usually have standard BSA bottom brackets and plenty of clearance.

-

Mountain Bikes (Full-Suspension): This is a significant compatibility challenge area.

-

Mid-Drives: Extremely difficult for most conversion kits. The motor unit often interferes with suspension pivots, linkages, or the rear shock itself. Unless the frame was originally designed with an integrated mid-drive mount or has ISCG tabs compatible with specific (rare) aftermarket solutions, conversion mid-drives are usually not possible.

-

Hub Motors: Can be a more feasible option. However, you must check for clearance throughout the suspension's entire travel range. Deflate the rear shock and cycle the suspension to ensure the tire doesn't hit the seat tube or seat, and the motor casing doesn't touch chainstays or seatstays at full compression. The added unsprung weight of a rear hub motor can also negatively affect rear suspension performance, making it feel less responsive.

-

-

Hybrid/Commuter Bikes: Generally very good candidates. They often feature sturdy frames (steel or aluminum), sensible geometry for added weight, standard bottom brackets, and sufficient mounting points or space for batteries.

-

Road Bikes: Lightweight construction can be a concern, especially with older or high-end racing frames not designed for additional torque and weight. Tire clearance is often limited, which might restrict your choice of wider, more robust ebike-suitable tires. Aggressive road geometry might not be comfortable when factoring in the ebike system's weight and changed handling.

-

Cruiser Bikes: Often have strong, simple frames that can be good candidates. However, check bottom bracket type (some older cruisers use non-standard Ashtabula/one-piece cranks) and dropout spacing carefully.

-

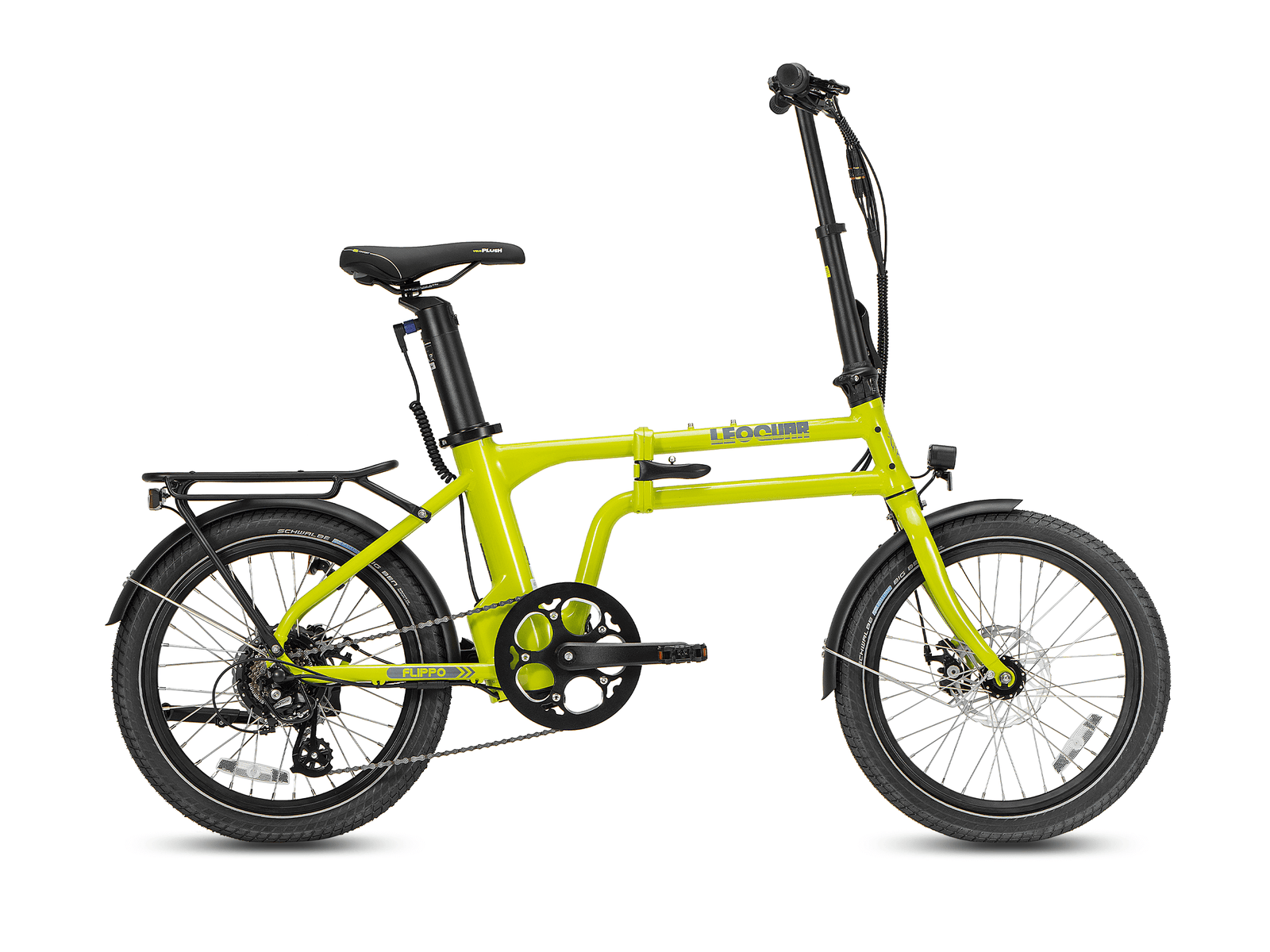

Folding Bikes: Space constraints for both the ebike motor and battery are major issues. Some specific, compact conversion kits exist for popular folding bike models, but it's a niche area.

-

Bottom Bracket Shell (Critical for Mid-Drives):

This is the make-or-break point for most mid-drive conversions.

-

Identification:

-

BSA Threaded: You'll typically see external bearing cups threaded into the frame. This is the most common and DIY-kit-friendly type.

-

PressFit: Bearings are pressed directly into a smooth bore in the frame. Examples include BB30, PF30, BB86, BB92. These require specialized adapters for most mid-drive kits, which can be problematic.

-

-

Measurement: Measure the width of the bottom bracket shell (the part of the frame the BB threads or presses into, not including any bearing cups). Standard BSA shells are 68mm (common on road/hybrid) or 73mm (common on MTB). Fat bikes use wider shells like 100mm or 120mm.

-

Most common DIY mid-drive kits like the Bafang BBS series are designed for 68-73mm BSA shells. As noted by sources like CyclingWeekly, "the frame material must be alloy and the bottom bracket width is 68–73mm – but that covers most bikes you're likely to be fitting this system to," confirming these are indeed standard bottom bracket specifications for common bikes.

-

Dropouts & Rear Triangle (Mainly for Hub Motors):

The rear of the frame needs careful scrutiny for hub motor installations.

-

Measuring OLD Accurately: Use calipers to measure the internal distance between the dropouts.

-

Assessing Dropout Material and Thickness: Steel is ideal. For aluminum, ensure the dropouts are at least 6-8mm thick, ideally more for higher power motors. Thinner aluminum dropouts are at high risk of damage without excellent torque arms.

-

Checking for Eyelets: If you plan to use fenders or racks, ensure their mounting eyelets don't interfere with the motor axle seating, wiring, or the placement of torque arms.

-

First-Hand Experience: We've seen cases where a dropout that seemed strong enough for a powerful hub motor eventually splayed open or cracked because a torque arm wasn't used, or wasn't installed correctly with good surface contact. It's a small part that makes a huge difference in transferring torque loads away from the dropout slot itself and onto a stronger part of the frame or fork.

-

Brake System Compatibility:

Upgrading to an ebike often means higher speeds and more weight, demanding better brakes.

-

Disc Brakes: Check your frame/fork's mount types (IS or Post Mount). Ensure chosen hub motor (if it has a disc rotor mount) is compatible. Rotor size limitations and clearance between the caliper and motor casing can also be factors.

-

Rim Brakes: If your hub motor kit includes a new wheel, ensure the rim has a compatible braking surface. Existing rim brakes may need upgrading to more powerful models (e.g., V-brakes over older cantilevers) for adequate stopping power.

-

Recommendation: We strongly recommend considering an upgrade to hydraulic disc brakes if converting a bike with older or weaker cable-actuated rim brakes or mechanical disc brakes. The improved power and modulation are significant safety benefits.

-

Space for Battery, Controller, and Wiring:

These components need a home.

-

Main Triangle: This is the most popular location for the battery, offering good weight distribution. Check if existing bottle cage mounts can be utilized for a battery cradle. If not, strap-on solutions are available, but ensure the frame tubes are strong enough. Measure the available space carefully against battery dimensions.

-

Rear Rack: An alternative for battery mounting, especially larger batteries. This shifts weight to the rear, affecting handling. Ensure the rack and its mounting points are robust.

-

Controller: Needs a protected spot, often near the bottom bracket, under the saddle, or in a frame bag.

-

Cable Routing: Plan how wires will be routed neatly and safely, away from moving parts, and secured to prevent snagging or abrasion.

-

Overall Frame Condition & Age:

An old or damaged frame is a poor candidate.

-

Thorough Inspection: Carefully examine the entire frame for any signs of cracks, especially around welds, the bottom bracket shell, headtube, and dropouts. Look for dents, significant rust (especially on steel frames), or evidence of previous crash damage or repairs. An old, heavily-used frame might not have the remaining strength to handle ebike stresses.

-

Headset and Bearings: Ensure the headset, wheel bearings, and bottom bracket bearings (if not being replaced by a mid-drive) are in good condition and properly adjusted to handle the extra load and potential speeds.

Troubleshooting Common Fitment Issues: Tips, Tricks, and When to Say "No"

Even with careful planning, you might encounter minor fitment challenges when installing your ebike motor. Some can be fixed; others mean you should stop.

-

For steel frames, it's often possible to slightly "cold set" or spread the rear dropouts to fit a slightly wider hub motor axle. For example, safely spreading a 135mm dropout to fit a 138mm hub motor axle is common. This involves gently and evenly pulling the dropouts apart. This should only be a few millimeters.

-

Do not try to spread aluminum or carbon fiber frames this way. These materials don't bend well and can crack or fail.

-

Sometimes, the flats on a hub motor axle might be a bit too large for the dropout slot. Careful filing of the dropout slot on steel or aluminum frames can allow the axle to fit properly. Make sure you file evenly and keep flat surfaces for the washers and nuts.

-

This is generally not recommended for carbon fiber dropouts due to the risk of damaging the composite structure.

-

For frames with PressFit bottom brackets, adapters exist that can convert them to a BSA-threaded interface, potentially allowing a standard mid-drive kit to be fitted.

-

However, be aware that these adapters can sometimes cause issues like creaking, alignment problems if not perfectly installed, or potentially stress the frame's BB shell in unintended ways. They add complexity and are not always a perfect solution.

-

For minor clearance issues with motor casings or achieving correct chainline, high-quality spacers or washers can sometimes be used. Always ensure components remain securely fastened and properly aligned. Avoid excessive stacking of spacers.

Red Flags – When Your Frame is a "No-Go":

Sometimes, a frame is simply not suitable, and forcing a conversion is unsafe or impractical.

-

Significant Frame Damage: Any visible cracks (especially around critical areas like welds, head tube, bottom bracket, or dropouts), bent tubes, or severe corrosion are immediate red flags.

-

Extremely Lightweight/Delicate Frames: High-end carbon fiber road racing frames, or very lightweight aluminum frames designed purely for speed and minimal weight, are often not engineered to withstand the additional torque, weight, and stresses from an ebike motor and battery.

-

Highly Proprietary Frame Designs: Some bicycles, particularly vintage models or those with unique suspension designs, may feature non-standard tube shapes, dropout configurations, or bottom bracket shells that offer no compatible mounting points for common conversion kits.

-

Incompatible Bottom Bracket Types: If your frame has a bottom bracket type for which no reliable conversion adapter exists for available mid-drive kits (e.g., some obscure PressFit standards or integrated systems), a mid-drive conversion may be impossible without extensive custom fabrication.

Always remember the importance of thoroughly checking ebike conversion kit compatibility before purchasing. This upfront research can save considerable frustration and expense.

Beyond the Frame: Other Critical Compatibility Checks for Your Ebike Project

While the frame is central, a successful ebike motor conversion demands a holistic view. Other components must also be compatible and up to the task.

Wheels:

If you're not using a hub motor kit that includes a pre-built wheel, ensure your existing wheels are strong enough to handle the increased forces and weight. The rim, spokes, and hub (especially for a non-motorized wheel carrying extra bike weight) should be in good condition. Wheel size (e.g., 26", 700c, 29") must match the kit specifications if it dictates.

Drivetrain:

Chainline can become an issue with mid-drive motor installations, potentially requiring a new chainring with a different offset, or bottom bracket spindle spacers to align the chain properly with the rear cassette. Your existing gears (cassette, derailleur, shifters) must be in good working order and able to handle the motor's power. A worn drivetrain will perform poorly and wear out even faster with an ebike motor.

Brakes (Revisited):

We cannot stress this enough: your brakes must be able to reliably stop the increased mass and potential speed of an ebike. If your bike has basic rim brakes or older mechanical disc brakes, seriously consider upgrading to hydraulic disc brakes or at least high-quality mechanical disc brakes with larger rotors.

Tires:

Ensure your tires are in good condition, with adequate tread. Consider tires specifically designed or rated for ebikes, as they often have more robust casings and compounds to handle higher speeds, increased loads, and greater mileage. Critically, ensure there is adequate clearance for your chosen tires within the frame and fork, especially if opting for wider ones.

Suspension (if applicable):

If your bike has suspension (front fork or rear shock), it should be in good working order, properly serviced, and ideally adjustable for preload and damping to accommodate the added weight of the ebike system. Consider if the existing suspension travel and performance characteristics are suitable for how you intend to use the converted ebike.

-

Before converting, you MUST check your specific local, state, and national ebike laws. Regulations vary widely regarding conversions, maximum motor power (often 250W in Europe/UK, 750W in many US states for street use), speed limits (e.g., assist cutting out at 20 mph / 32 kph for Class 1/2, 28 mph / 45 kph for Class 3 in the US; 25 km/h for L1e-A pedelecs in the EU), age restrictions, and where you can legally ride.

-

Warranty: Installing an ebike motor on a standard bicycle will almost certainly void any existing warranty from the bicycle manufacturer. This is a financial risk to consider.

The Installation Journey: What Frame Compatibility Means in Practice

The compatibility checks you perform directly translate into the ease (or difficulty) of the physical installation of the ebike motor.

For a typical hub motor installation, correct dropout spacing is paramount. If the OLD is off, you'll struggle to insert the wheel. The axle must fit snugly in the dropouts; too loose, and it can move; too tight, and it won't seat. Torque arm mounting is critical – ensuring it has a solid anchor point on the fork leg or frame stay and that its fasteners are secure prevents the axle from spinning and damaging the dropouts.

With a mid-drive motor, the bottom bracket is the star. If it's not a compatible BSA threaded shell of the correct width, you're already facing major hurdles. Once the BB is sorted, the motor housing must clear the chainstays, downtube, and seat tube. Sometimes, a seemingly perfect BB fit is thwarted by a chainstay that's too close or a suspension pivot that interferes.

You'll likely need some specialized bicycle tools, such as a crank puller, the correct bottom bracket tool for your bike's existing BB type (and potentially for the motor's lockrings), and a cassette lockring tool and chain whip if swapping cassettes.

First-Hand Experience: We remember one project where a mid-drive motor technically fit the bottom bracket shell perfectly, but once loosely mounted, the motor casing then fouled on the lower chainstay during initial mock-up of suspension compression – something only discovered mid-build because full travel wasn't checked initially. This highlights why checking clearances dynamically (especially with full suspension bikes by letting air out of the shock and cycling it) is vital, not just static fit.

Always prioritize safety when working with tools, heavy mechanical parts, and electrical systems. If you are unsure about any step, or if the compatibility seems questionable, seeking help from a professional ebike mechanic is a wise move.

Conclusion: Making an Informed Decision About Your Ebike Conversion

To revisit our core question: Can You Install an Ebike Motor on Any Frame? Compatibility Tips point to a nuanced "yes, but." While not every bicycle frame is a suitable candidate for an ebike motor, many can be successfully and safely converted with careful assessment and the right choice of conversion kit.

The most important takeaway is that understanding your specific bike frame – its material properties, its design (especially the bottom bracket area and dropouts), and its current structural condition – is absolutely essential. These are the factors that determine whether an ebike motor can be integrated effectively.

A successful, safe, and enjoyable DIY ebike conversion depends on thorough upfront research and carefully matching the ebike motor kit to your frame's characteristics, rather than trying to force an incompatible fit. We encourage you to re-read the relevant sections of this guide and use the provided checklists methodically.

If, after your assessment, you have any doubts – particularly if dealing with valuable, lightweight, or structurally complex frames like carbon fiber or full-suspension mountain bikes – consulting a qualified and experienced ebike mechanic is a wise investment. Their expertise can prevent costly mistakes and ensure your safety.

Ultimately, a well-researched and carefully executed DIY ebike conversion can be an incredibly rewarding project, transforming a familiar bicycle into an exciting new mode of transport and adventure.

FAQs

1. What types of bike frames are best for ebike motor conversions?

Steel and aluminum frames are generally the most suitable for conversions, with steel being the most forgiving. Mountain bikes (hardtail), hybrid bikes, and sturdy commuter bikes typically make excellent candidates.

2. Can I install an ebike motor on a carbon fiber frame?

Installing motors on carbon fiber frames carries significant risks and is generally discouraged. If attempted, it requires extremely careful mounting with proper torque arms and distributed clamping forces to avoid catastrophic frame failure.

3. What's the difference between hub motors and mid-drive motors for compatibility?

Hub motors mount in the wheel and require compatible dropout spacing and strong dropouts, while mid-drive motors attach at the bottom bracket and require specific BSA threaded shells (typically 68-73mm) and adequate clearance around the bottom bracket area.

4. How do I measure if my bike's bottom bracket is compatible with a mid-drive motor?

Measure the width of your bottom bracket shell (typically 68mm for road/hybrid or 73mm for MTB). Most DIY mid-drive kits like Bafang BBS work with BSA/English threaded bottom brackets of these dimensions, not with PressFit systems without adapters.

5. What safety upgrades should I consider when converting my bike to an ebike?

Consider upgrading to hydraulic disc brakes for better stopping power, installing ebike-rated tires for durability at higher speeds, ensuring proper torque arms for hub motors, and thoroughly checking frame integrity before conversion.

Leave a comment