Ebike Throttle Not Working or Responding? Diagnose It in 5 Minutes

Why Your Ebike Throttle Stops Working

It's one of the most frustrating moments for any ebike rider. You're geared up, helmet on, ready to enjoy the freedom of electric power, but when you press the thumb throttle or twist the grip... nothing happens. The bike is on, but the motor is silent. Before you start worrying about expensive repairs or a trip to the bike shop, take a breath. We're here to help you get your power back. When an ebike throttle is not working, the cause is rarely a major failure.

In our experience working with hundreds of ebikes, over 80% of throttle issues are resolved with the simple checks we're about to show you. Often, the culprit is something as simple as a loose wire or a slightly engaged brake lever that activates the motor cut-off switch. This guide will walk you through a simple, step-by-step diagnostic process that anyone can follow, regardless of technical skill. Let's get you back on the road.

The 5-Minute Diagnostic Test

Follow these steps in order. They start with the easiest and most common fixes, requiring no tools. Don't skip a step, as it could save you a lot of time. Each step builds on the previous one to help you find the problem quickly.

Step 1: Power and Display Check

This seems obvious, but it's the foundation of all troubleshooting. Make sure your battery is securely locked into its mount. A slightly loose battery can cause intermittent power cuts that might seem like a throttle issue. Turn the system off and on again to reset any temporary glitches.

Does the display show any error codes? Your bike's display is its communication tool that tells you what's wrong. Look for any electric bike error numbers or symbols on the screen. Common throttle-related codes are "Error 04" or "Error 05," which often indicate a throttle fault or that the throttle was not in its zero position at startup. For a comprehensive list of codes for various systems, check out community resources like many ebike forum discussions on error codes. These forums have helped thousands of riders solve similar problems.

Step 2: The Brake Lever Check

This is the single most common reason for a non-responsive throttle. Your ebike has a safety feature called a brake cut-off sensor that immediately cuts power to the motor when you pull a brake lever, preventing the motor from fighting against the brakes.

Check your brake levers carefully to see if either of them is slightly pulled, even by a few millimeters. This can happen if the bike was bumped or if the lever is a bit sticky after a ride. Firmly push both levers forward into their resting position. You should feel them settle completely against the handlebar grip. Test the throttle again to see if this fixed the problem. If it now works, you've found your problem and saved yourself a trip to the repair shop.

A sticky lever might need a drop of lubricant at its pivot point to prevent this from happening again. This is the first thing we check when a customer says their ebike throttle not working.

Step 3: The "Wire Wiggle" Test

Ebikes endure vibrations during normal riding, and over time, connectors can work themselves loose. The throttle connector is a primary suspect when the throttle stops responding. Locate the throttle wire by tracing the cable coming from your throttle assembly. You're looking for a connector, usually a few inches from the throttle itself, before the main wiring harness disappears into the frame.

It's typically a small, waterproof, 3-pin connector, often with color-coded arrows for alignment. Carefully pull the two halves apart to inspect the connection. Inspect the pins to see if any are bent or corroded from moisture. Blow out any dust or debris that might be blocking the connection. Then, align the arrows and push the connector firmly back together until you feel or hear a click. A secure connection is crucial for proper throttle operation. As many riders on forums like Reddit have found, a simple reconnect often solves the mystery. This simple fix has saved countless riders from expensive repairs.

Step 4: Throttle Housing Check

Next, let's look at the physical throttle unit on your handlebar. Start by visually inspecting the housing to see if you notice any cracks from a fall or impact. Check the throttle action to make sure the thumb paddle or twist grip moves freely. Is it blocked by a neighboring grip or brake lever that might have shifted position?

Is the throttle sticky or does it fail to spring back to the "off" position when you release it? Debris or grime can sometimes work its way inside the housing and cause these problems. Check for looseness by grabbing the entire throttle assembly and seeing if it rotates on the handlebar. If it's loose, use the appropriate Allen key to tighten the clamping bolt. A loose housing can strain the internal wiring and cause intermittent connection problems. Make sure it's snug but don't overtighten it.

Step 5: The Walk-Assist Mode Test

This is a clever diagnostic trick that can tell you a lot about your bike's electrical system. Most ebikes have a "walk" or "walk-assist" mode, which powers the motor at a slow walking speed. Activate walk-assist mode, which is usually done by holding down the "minus" or "down" button on your handlebar control. Check your owner's manual if you're not sure how to activate this mode on your specific bike.

Does the motor engage and start turning the wheel slowly? If the wheel starts turning, that's great news for your diagnosis. It tells you that the battery, controller, and motor are all communicating and functioning correctly. This strongly suggests the problem is isolated to the throttle unit itself or its specific wiring, not the entire power system.

Beyond the Basics: A Deeper Dive

If the 5-minute test didn't solve your throttle not working on ebike problem, let's dig a little deeper. These steps will help you pinpoint more complex failures that require a bit more investigation.

The Brake Cut-off Sensor

We mentioned this is the number one culprit, and it deserves a closer look. Sometimes just pushing the lever isn't enough if the sensor itself is misaligned or faulty from normal wear and tear. On mechanical brakes, the sensor is often a small box with a wire coming out, and a tiny plunger or switch is activated by the brake lever. For hydraulic brakes, the sensor is usually integrated into the lever body, often triggered by a small magnet glued to the lever.

We once had a bike in the shop where a tiny magnet for the brake sensor had shifted by just 2mm after a minor bump, disabling the throttle completely. A simple dab of superglue was the permanent fix that got the rider back on the road. To rule out a faulty sensor, you can temporarily disconnect the brake sensors for testing purposes only. Trace the wires coming from both your brake levers, as they will have their own connectors just like the throttle. Disconnect the rear brake sensor first and test the throttle. If it still doesn't work, reconnect it and disconnect the front brake sensor, then test the throttle again. If unplugging a sensor makes the throttle work, you've found the faulty component.

Safety Disclaimer: Do not ride the bike with a brake sensor disconnected, as it is a critical safety feature. This test is for diagnosis only, and you should replace the faulty sensor before riding. Riding without working brake sensors can be extremely dangerous.

Tracing Wires Like a Pro

A wire can be damaged anywhere along its path from vibration, pinching, or moisture. You need to inspect it carefully from end to end. Inspect the full cable length by starting at the throttle and slowly running your fingers along the cable, feeling for any bumps, kinks, or flat spots. Look for any frayed or exposed copper wire that might be causing a short circuit.

Pay attention to stress points where damage is most common. The most frequent area for wire damage is around the head tube (where the handlebars turn), as the cable flexes during steering and can get pinched over time. Also, check anywhere the cable is held by a zip tie, as an overtightened tie can crush the internal conductors. Sometimes the damage isn't visible on the outside but the wires inside are broken.

Using a Multimeter Simply

This might sound advanced, but it's the definitive way to test a throttle. We'll make it easy so anyone can do this test. A multimeter is an inexpensive tool that can tell you if your throttle is getting power and sending a signal. First, you need to understand the three wires on a typical ebike throttle. Power wire is usually red and receives a constant 5 volts from the controller. Ground wire is usually black and provides the return path for the circuit. Signal wire is usually green, white, or blue and sends a variable voltage back to the controller, telling it how much power you're requesting. Here's how to test it, with great visuals available in resources like this detailed video guide on throttle voltage testing.

Set your multimeter by turning the dial to the 20V DC setting (or the setting just above 5V). Access the connector by unplugging the throttle connector and turning the ebike's power on. Test for Power by touching the multimeter's red probe to the pin for the red wire and the black probe to the pin for the black wire (on the side of the connector coming from the bike, not the throttle). You should see a reading of approximately 4.5V to 5V.

If you have around 5V, the controller is sending power correctly. If you have 0V, the problem is likely in the main wiring or the controller, not the throttle itself. Test for Signal by reconnecting the throttle and carefully inserting the multimeter probes into the back of the connector to make contact with the metal parts of the signal and ground wires. With the throttle at rest, you should see a voltage of around 0.8V to 1V.

Now, slowly engage the throttle and watch the voltage reading. The voltage should smoothly increase to around 3.6V to 4.2V at full throttle. If the voltage increases smoothly, your throttle is working perfectly and the problem is elsewhere. If the voltage stays at 0V, or doesn't change when you activate the throttle, you have confirmed a faulty throttle that needs replacement.

Symptom-to-Solution Chart

Use this quick reference table to match your specific problem to the most likely cause. This will help you focus your troubleshooting efforts on the most probable solutions first.

| Symptom | Most Likely Cause(s) | What to Do First |

|---|---|---|

| Throttle is completely dead, no response at all. | 1. Brake cut-off sensor engaged. 2. Loose throttle connector. 3. No power to throttle. |

Check brake levers (Step 2). Check the main throttle connector (Step 3). |

| Throttle works intermittently or cuts out. | 1. Damaged/frayed wire. 2. Loose pin inside connector. 3. Water in the connector. |

Inspect the full length of the wire. Unplug, inspect pins, and reconnect securely. |

| Throttle doesn't spring back to 'off' position. | 1. Physical damage or obstruction. 2. Internal spring failed. 3. Dirt/grime inside the housing. |

Visually inspect the throttle for debris (Step 4). A replacement is likely needed. |

| Pedal assist works, but throttle does not. | 1. Faulty throttle unit. 2. Damaged throttle wiring. 3. Controller settings (throttle disabled). |

This strongly points to the throttle itself. Perform the multimeter test to confirm. |

When to Replace Your Throttle

If you've completed the multimeter test and confirmed the throttle is faulty (i.e., it receives 5V power but sends no changing signal voltage), it's time for a replacement. A throttle is a sealed unit that is not designed to be repaired internally. When buying a replacement, two things are critical for compatibility. First, ensure it's a standard 5V throttle, which covers nearly all ebikes on the market today.

Second, and most importantly, get a throttle with the exact same connector type and pin configuration as your old one. If you can't find an exact match, you may need to splice the wires, but this requires more skill and electrical knowledge. Buying from your bike's original manufacturer is the safest bet for compatibility. They will have the exact specifications and connector type that your controller expects.

Proactive Throttle Care

An ounce of prevention is worth a pound of cure when it comes to ebike maintenance. To avoid having your ebike throttle not working in the future, follow these simple maintenance tips that take just a few minutes.

Once a month, give your throttle and brake lever connectors a quick wiggle to ensure they're snug. This simple check can catch loose connections before they become a problem. Make sure the throttle cable has enough slack to move freely as you turn the handlebars. Avoid tight zip ties that can pinch the wire and cause internal damage over time. Keep your handlebar controls clean by wiping them down after a muddy or dusty ride. This prevents grime from working its way into the throttle mechanism and causing it to stick or malfunction.

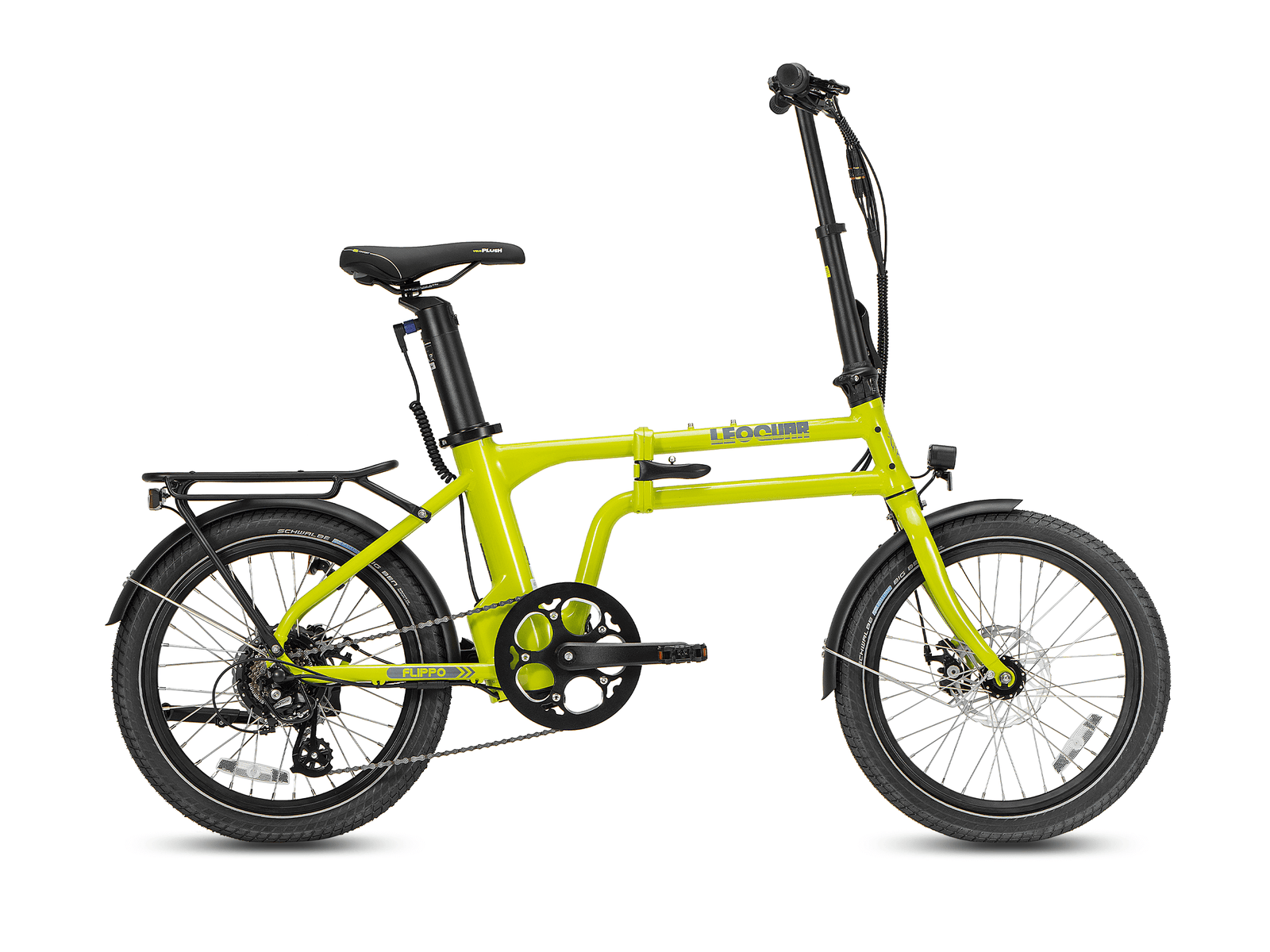

Protect your throttle from impact by being mindful when parking or transporting your foldable eletric bike. A direct hit to the throttle housing is a common cause of failure that's easily preventable. Store your ebike in a dry place when possible to prevent moisture from getting into electrical connections. If you must ride in wet conditions, check your connections afterward and dry them if necessary.

Frequently Asked Questions

Q: Why does my ebike throttle work sometimes but not others?

A: Intermittent throttle problems are usually caused by loose connections or damaged wires. Check your throttle connector first, then inspect the wire for any damage along its length. Water in the connector can also cause this issue.

Q: Can I ride my ebike if the throttle isn't working but pedal assist still works?

A: Yes, you can safely ride using only pedal assist. However, you'll lose the convenience of throttle-only power for situations like starting from a stop or climbing steep hills without pedaling.

Q: How much does it cost to replace an ebike throttle?

A: A replacement throttle typically costs between $15-40 for the part itself. If you have a bike shop install it, expect to pay an additional $30-50 for labor, though it's a simple job most riders can do themselves.

Q: Will disconnecting my brake sensors for testing damage my ebike?

A: No, temporarily disconnecting brake sensors for testing won't damage your ebike. However, never ride with them disconnected as they're critical safety features that prevent the motor from working when you're braking.

Q: How can I tell if my throttle problem is the throttle itself or the controller?

A: Use the walk-assist mode test. If walk-assist works but the throttle doesn't, the problem is likely the throttle unit or its wiring. If walk-assist also doesn't work, the issue may be with the controller or main electrical system.

Leave a comment