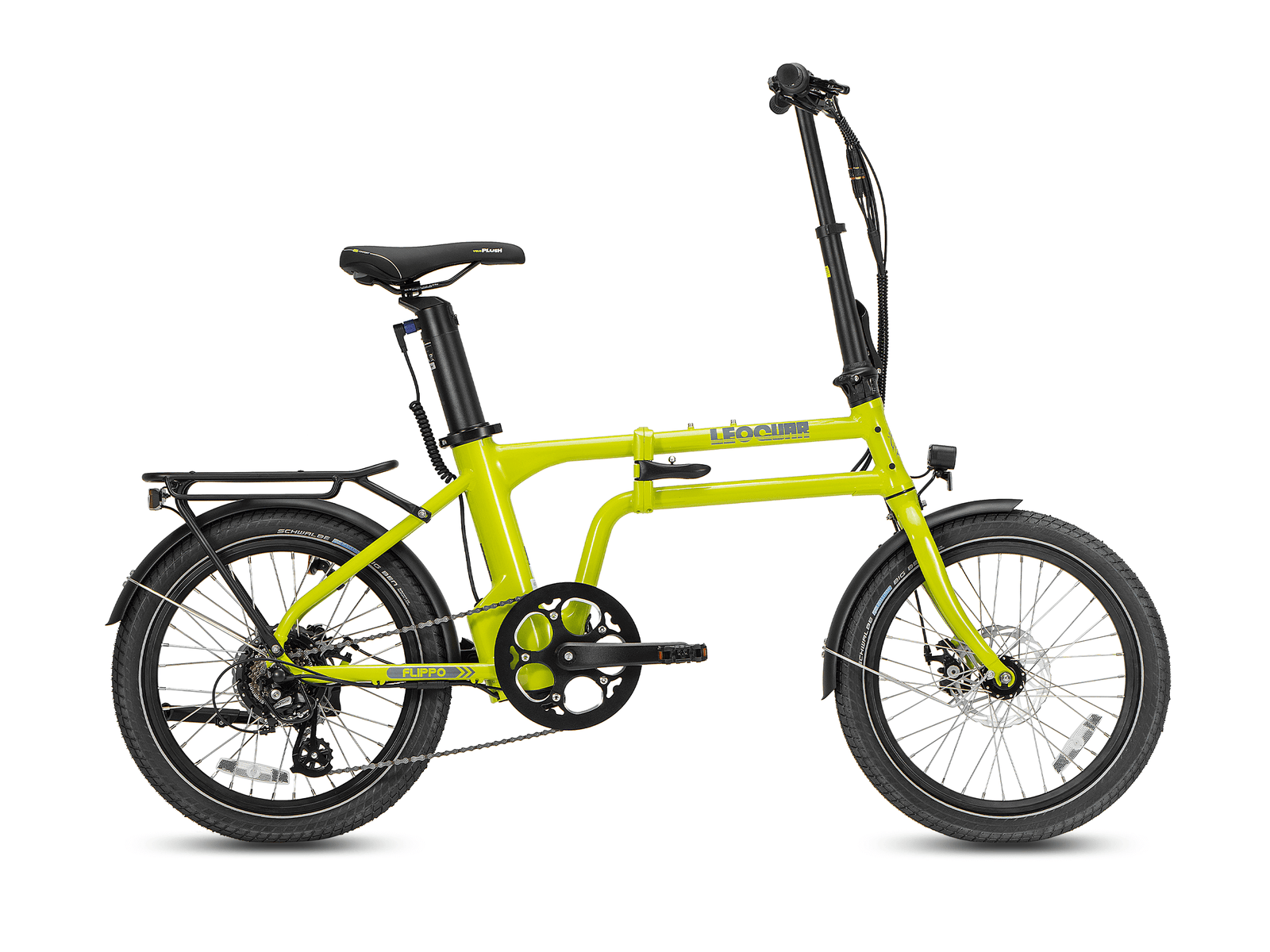

Beyond the Ebike Factory: Leoguar E Bike OEM Brings Better Control & Quality

Not All Factories Equal

When you search for an "ebike factory," you're likely picturing a place where frames are welded, components are installed, and finished bikes roll off the line. While that's part of the story, it's not the most important part. The critical factor that determines the quality, performance, and long-term value of your e-bike is the business model behind the factory.

The e-bike industry is experiencing a massive boom. Forecasts predict substantial growth in the e-bike market. This explosion has attracted a wave of new brands, but they operate on two fundamentally different models. The most common is the white-label assembler. This is a brand that simply puts its logo on a generic, pre-designed bike. The other, far more integrated model, is the true Original Equipment Manufacturer (OEM). This is a company that designs, engineers, and manufactures the product from the ground up.

The difference between a rebranded product and a brand-engineered one is everything. As a company that has been an OEM for decades, we believe discerning riders deserve to know what truly happens inside the factory walls.

The White-Label Reality

What really goes on in a typical, non-integrated ebike factory? This model, often called white-labeling or Original Design Manufacturing (ODM), is the industry's most common shortcut. It allows new companies to enter the market quickly, but often at the expense of the end user. In this scenario, a brand approaches a large factory that has a catalog of pre-designed e-bikes. They select a model, choose a color, and request their logo be applied.

The brand itself has minimal involvement in the engineering or production. While this can result in a lower upfront cost, it introduces significant risks and compromises that you, the rider, will feel. This approach has several inherent downsides:

Limited Design Input: The brand has little to no control over the core engineering. Frame geometry, motor placement, battery integration, and weight distribution are all predetermined. This means the bike isn't optimized for a specific ride feel; it's designed to be a generic template.

Inconsistent Quality Control: When a brand doesn't own or directly manage the production line, quality control becomes a matter of trust, not verification. Inspections are often superficial, focusing on cosmetic finish rather than the critical structural and electrical systems. The brand is simply a customer of the factory, not the master of the process.

"Franken-bikes": To hit a low price point, these factories often source components from a mix of anonymous, low-bid suppliers. The motor, battery, controller, and display may not be designed to work together as a cohesive system. This leads to inefficient performance, jerky power delivery, and potential compatibility nightmares down the road.

Lack of Long-Term Support: Because the brand didn't design the bike, they often lack the deep technical knowledge to provide expert support. Worse, they may have no reliable source for proprietary replacement parts like battery mounts or motor housings, leaving you stranded if a specific component fails years later.

The OEM-to-Brand Advantage

There is a better way. Before Leoguar sold a single bike under our own name, we spent decades as an Original Equipment Manufacturer (OEM). This means we were the factory and engineering partner behind the scenes, building complex, high-performance e-bikes for well-known global brands. This transition from a behind-the-scenes expert to a direct-to-consumer brand is the Leoguar difference.

It's an advantage built on a foundation of proven manufacturing expertise. Having manufactured over 200,000 e-bikes for global brands, we've encountered and solved nearly every possible engineering and supply chain challenge. This institutional knowledge is now baked into every Leoguar e bike. We didn't just decide to sell e-bikes; we evolved from building them for others to building them for you, carrying forward all the lessons learned, supply chain relationships, and quality control systems we perfected along the way.

This commitment to in-house control is a hallmark of the world's most serious manufacturers. As top-tier automotive and cycling companies demonstrate, a deep investment in production is non-negotiable for quality. We see this trend in how serious brands are investing in their own manufacturing capabilities, a philosophy we have embodied for years. To make the distinction clear, here is how the two models compare:

| Feature | White-Label Reseller | OEM-to-Brand (Leoguar) |

|---|---|---|

| Design & Engineering | Selects from a pre-made catalog. No control over frame or system design. | In-house team designs the frame, geometry, and component integration from a blank slate. |

| Quality Control | Relies on the factory's basic, often superficial, checks. No direct oversight. | Owns and manages a multi-stage QC process on the production line and post-assembly. |

| Component Sourcing | Often uses the cheapest available parts to meet a price point. Inconsistent suppliers. | Leverages long-term relationships with top-tier suppliers (Shimano, Tektro, Maxxis) to secure reliable, high-performance parts. |

| System Integration | Components (motor, battery, controller) are pieced together, not designed as a system. | Motor, battery, sensors, and software are engineered to work together for a smooth, efficient, and intuitive ride. |

| Rider Support & Parts | Limited technical knowledge. struggles to source unique replacement parts. | Deep product expertise for support. Maintains a full inventory of proprietary and standard parts for long-term service. |

| Long-Term Value | Low initial cost but higher risk of performance issues, failures, and obsolescence. | Higher intrinsic quality, reliability, and serviceability, resulting in a better ownership experience and lasting value. |

A Blueprint for Quality

Saying we have better quality control isn't enough. We believe in showing our work. Our OEM background gives us total command over the production process, allowing us to implement a rigorous blueprint for quality that is impossible in a white-label model. This is how an exceptional e-bike is truly built, step by step.

Step 1: Integrated Design & Engineering

Our process begins not in the factory, but at the design table. We don't just pick a frame and try to fit a motor into it. We design the frame, motor mounts, battery housing, and internal cable routing as a single, cohesive system. This allows us to perfect weight distribution for balanced handling and integrate advanced features seamlessly.

For example, a high-fidelity torque sensor, which provides the smoothest and most intuitive pedal assistance, requires precise frame integration. This is an engineering feat that is difficult, if not impossible, to execute within the constraints of a generic, pre-made frame.

Step 2: Vetted Component Supply Chain

An e-bike is only as good as its weakest part. Our decades as an OEM have allowed us to build strong, long-term relationships with the best component suppliers in the world. We don't just order parts; we co-develop and specify them to meet our standards. When we source from established motor manufacturers like Bosch and Shimano or use brakes from Tektro and tires from Maxxis, we are leveraging a trusted network that guarantees performance and reliability. A white-label brand simply gets whatever the factory has on hand. We get exactly what our design demands.

Step 3: Rigorous In-Line & Post-Assembly Testing

This is where our control of the factory floor pays off. Every Leoguar e bike undergoes a battery of tests that go far beyond a simple visual check.

Key processes include frame weld integrity tests using stress analysis to ensure structural soundness, multi-cycle battery cycle testing to verify capacity and health, and dynamometer testing for motors to confirm power and torque outputs are within specification. After full assembly, each bike undergoes a final 10-point pre-shipment inspection, checking everything from brake alignment and gear indexing to electrical connections and torque settings.

Step 4: Certification and Safety as a Priority

For many brands, safety certifications are a final hurdle to clear before selling. For us, they are a foundational part of the design process. Because we engineer the entire electrical system—battery, controller, and motor—we build our bikes to meet and exceed the most stringent safety standards from the start. Achieving certifications like UL and TÜV isn't an afterthought; it's a direct result of our deep product knowledge and control over every component and connection. This ensures your bike is not only high-performing but fundamentally safe.

What This Means For You

All this talk of OEM control, supply chains, and factory processes ultimately comes down to one thing: a better ride and a more reliable e-bike for you. We translate our manufacturing expertise into tangible benefits that you will feel from your very first pedal stroke.

- Because we control the engineering from the ground up, you get a perfectly balanced bike with intuitive handling. The bike feels stable and predictable, with no weird creaks or rattles that plague poorly assembled machines.

- Because we integrate the motor and torque sensor at the design stage, you get a ride that feels powerful yet natural. The assistance is smooth and instantaneous, responding to your effort like an extension of yourself, not a clunky motor strapped to a frame.

- Because we manage our own quality control and parts inventory, you get peace of mind. You can ride with confidence, knowing that your bike was built to last and that expert support and compatible replacement parts are always available if you ever need them.

- Because we are the factory, you get exceptional value. By designing, manufacturing, and selling directly to you, we eliminate the multiple layers of importers, distributors, and brand markups common in the white-label model.

You are investing in engineering and quality, not middlemen.

The Choice Is Clear

When you choose an e-bike, you're choosing more than just a product; you're choosing the philosophy of the company that built it. You can opt for a brand that simply puts its logo on someone else's work, or you can invest in a brand that builds.

The difference lies in the integrity of the design, the quality of the components, and the confidence that comes from knowing your bike was engineered and assembled by experts who control the process from start to finish. An e-bike is an investment in your freedom, your health, and your enjoyment. Make sure that investment is built on a foundation of true manufacturing excellence. The choice is not just about the ebike factory; it's about the expertise inside it.

Frequently Asked Questions

1. Q: What's the main difference between white-label and OEM e-bike manufacturers?

A: White-label brands simply put their logo on pre-made bikes from a catalog, while OEM manufacturers like Leoguar design and engineer the entire bike from scratch. This means OEM brands have complete control over quality, components, and performance, while white-label brands rely on whatever the factory provides.

2. Q: Why does it matter if a brand controls its own manufacturing?

A: When a brand controls manufacturing, they can ensure consistent quality, use better components, and provide long-term support. They also have deep knowledge of how every part works together, which means better customer service and reliable replacement parts when needed.

3. Q: How can I tell if an e-bike brand is white-label or OEM?

A: Look for brands that talk about their engineering process, component relationships, and manufacturing history. OEM brands like Leoguar will have detailed information about their design philosophy and quality control processes. White-label brands often focus more on marketing and less on technical details.

4. Q: Are white-label e-bikes always bad quality?

A: Not necessarily, but they come with higher risks. Since the brand doesn't control the engineering or manufacturing process, quality can be inconsistent. You might also face challenges getting replacement parts or technical support since the brand didn't actually design the bike.

5. Q: What should I look for when choosing an e-bike manufacturer?

A: Look for brands that design their own bikes, have long-term relationships with quality component suppliers, offer detailed technical support, and maintain inventory for replacement parts. Also check for proper safety certifications and evidence of rigorous quality testing processes.

Leave a comment