Axle Bearing Failures in Electric Bikes: What You Need to Know

Axle bearing failures are a common issue that can affect the performance and safety of electric bike. Key factors, such as overloading and inadequate maintenance, can lead to these failures. Symptoms like unusual noises and wheel wobble may indicate that your bearings are in trouble.

In this article, we'll discuss these causes and symptoms in more detail, enabling you to keep your electric bike running smoothly.

Understanding Axle Bearings in Electric Bikes

Axle bearings are small but crucial components of an electric bike. They allow the wheels to rotate smoothly with minimal friction. In essence, these bearings facilitate the motion of the wheel around the axle, supporting the weight of the bike and rider while ensuring a seamless ride.

How Do Bearings Work?

Bearings are designed to reduce friction between moving parts. In electric bikes, the axle bearings are typically ball bearings or roller bearings. These tiny spheres or cylinders sit between the wheel hub and the axle, providing a smooth surface for rotation.

Ball bearings are most common due to their ability to handle both radial and axial loads, which makes them versatile for different riding conditions. However, if they become damaged or worn out, the performance of your electric bike can be significantly affected.

Symptoms of Bad Bearings in Electric Bikes

Identifying the symptoms of failing axle bearings early can prevent further damage to your electric bike. Here are some common signs that indicate your bearings might need attention:

Unusual Noises

One of the first signs of axle bearing failure is unusual noise coming from the wheel area. You might hear grinding, clicking, or humming sounds as the bike moves. These noises typically indicate that the bearings are worn out and need to be replaced.

Reduced Performance

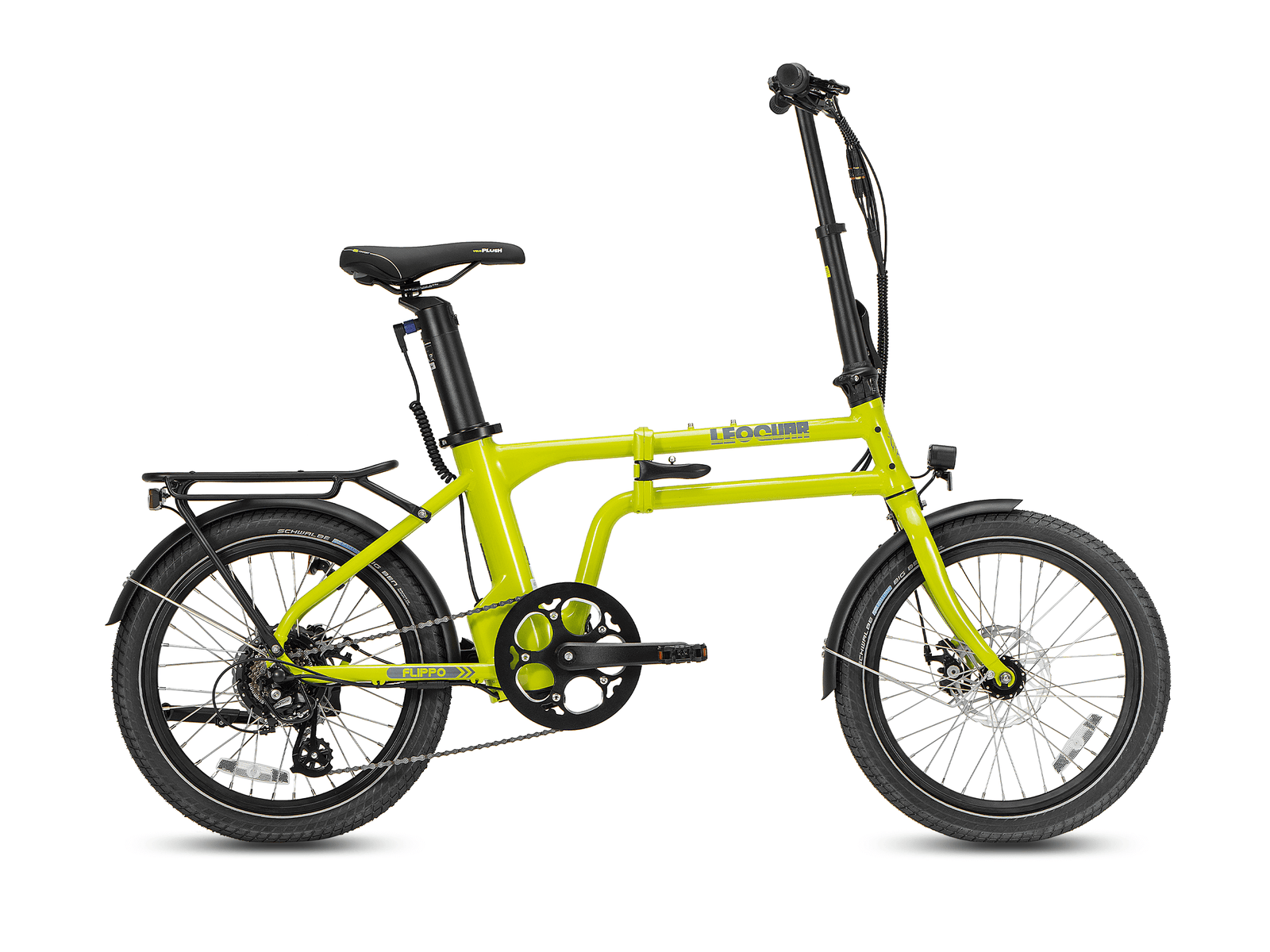

A decline in your bike's performance can also point to bearing issues. If you notice that your 20 inch wheel bike isn't accelerating as smoothly or if there's increased resistance while pedaling, it might be time to check the bearings.

Wheel Lock-Up

If you experience wheel wobble or notice that the wheel isn't spinning as freely as it should, this could be a sign of worn bearings. A wobbly wheel can affect your bike's handling and safety, so addressing this issue promptly is crucial.

Vibration

Excessive vibration felt through the handlebars or pedals can indicate bad bearings. When bearings wear out or become misaligned, they can cause uneven wheel rotation, resulting in uncomfortable vibrations during your ride. This issue can escalate if not addressed, potentially damaging other bike components.

Causes of Axle Bearing Failures

Axle bearing failures in electric bikes can occur for several reasons. Understanding these causes can help in preventing future issues and ensuring a smooth ride.

Overloading

Exceeding this limit can place excessive pressure on the axle bearings, which are not built to handle extra weight. This overloading can cause the bearings to wear out more quickly than they normally would.

The resulting strain can lead to heat buildup, which further exacerbates the deterioration of the bearings. Over time, this can result in premature wear and eventual failure, potentially leading to unsafe riding conditions.

Lack of Maintenance

Neglecting to lubricate axle bearings or skipping regular check-ups can lead to dirt, dust, and debris accumulation, which can wear down the bearings.

Without adequate lubrication, the friction between moving parts increases, leading to overheating and corrosion. A well-maintained bike not only performs better but also enhances safety and reliability.

Exposure to Harsh Conditions

Riding your electric bike in harsh conditions, such as heavy rain, mud, or on rough terrains, can expose the axle bearings to moisture and contaminants.

Water intrusion can lead to rust and corrosion within the bearings, compromising their structural integrity. Dust and mud can also infiltrate the bearings, creating abrasive conditions that accelerate wear. Regular cleaning and protection from the elements can significantly extend the life of your axle bearings.

Wear and Tear

Over time, all mechanical components experience wear and tear, and axle bearings are no exception. Factors such as the quality of bearings used, riding style, and frequency of use play significant roles in the rate of wear.

Preventing Axle Bearing Failures

Preventing axle bearing failures involves a combination of proper electric bike maintenance and mindful riding habits. Here are some tips to help prolong the life of your bearings:

Regular Inspections: Perform regular inspections to check for any signs of wear or damage. Look for dirt buildup, listen for unusual noises, and check the wheel's movement for any abnormalities.

Proper Lubrication: Lubricating the bearings is crucial in reducing friction and preventing wear. Use a high-quality lubricant recommended by your bike manufacturer and apply it according to their guidelines.

Avoid Overloading: Be mindful of the weight you carry on your electric bike. Avoid exceeding the recommended weight limit to prevent putting unnecessary strain on the bearings.

Protect from Elements: Whenever possible, avoid riding in harsh weather conditions. If you must ride in the rain or mud, ensure your bike is cleaned and dried thoroughly afterwards to remove any contaminants that could affect the bearings.

Leave a comment