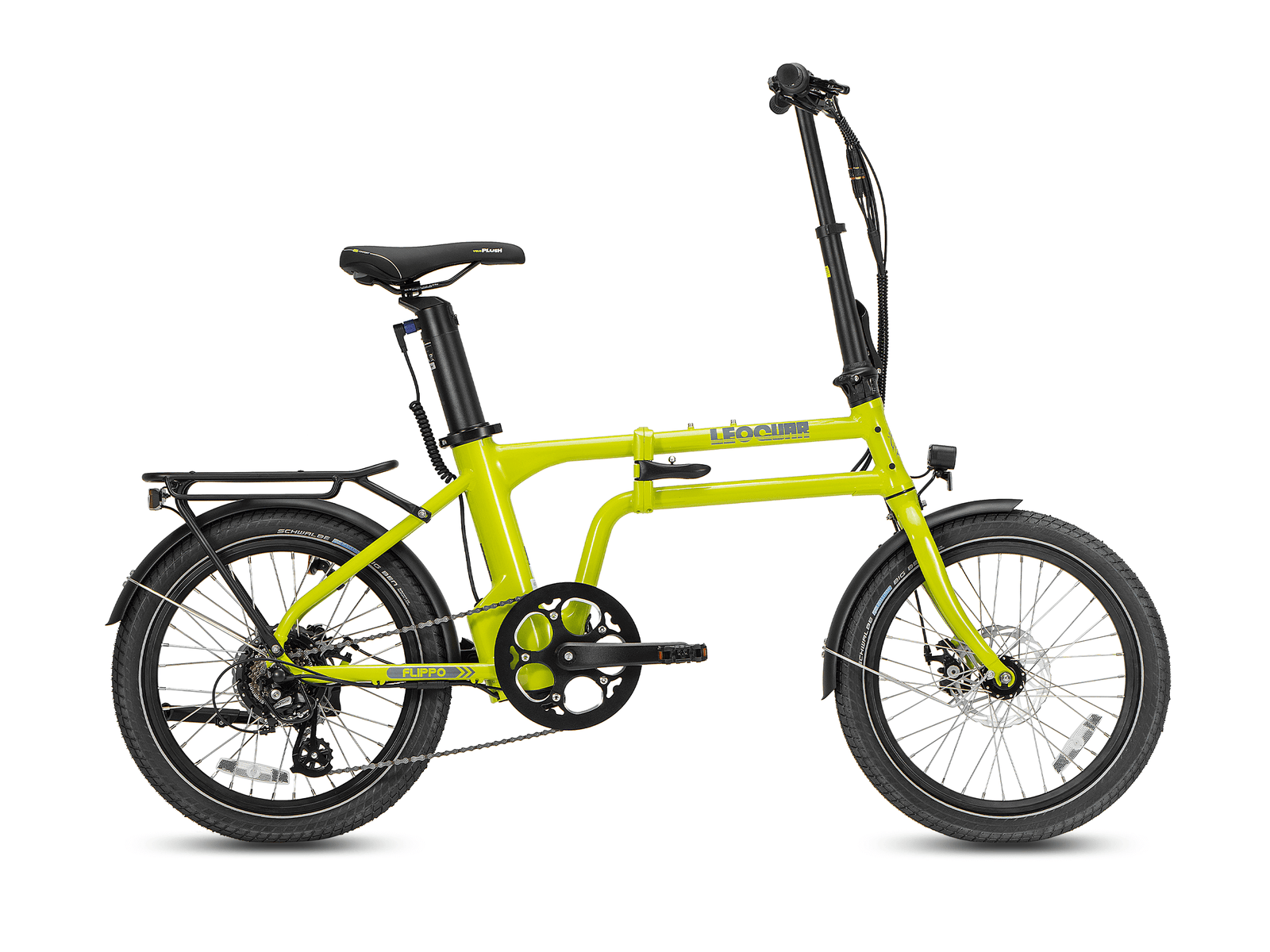

How Do I Remove My eBike Pedals?

Understanding E-Bike Pedal Basics

Changing your e-bike pedals might seem scary at first. But the main job is simple—though the extra weight and electronics of an e-bike need more care. Whether you're replacing bike pedals for a better fit or upgrading to removable bike pedals, the most important rule to remember is this: the right pedal follows the usual "Righty-Tighty, Lefty-Loosey" rule.

This reverse threading on the left pedal is smart engineering. It stops the pedal from coming loose while you ride because of something called precession. This is a well-known idea in bike repair, as shown by sources like the late, great Sheldon Brown's guide to the principle of pedal threading. While this works for all bikes, an e-bike's heavy frame, motor, and wires mean you can't just force your way through the job. This guide will show you everything from getting the right tools to preparing your e-bike, removing stuck pedals, and putting in new ones the right way.

Essential Tools and Preparation

Getting the right tools before you start makes the difference between a quick job and a long, frustrating day. It also keeps your bike parts from getting damaged. We suggest gathering everything you need first so the work goes smoothly.

| Tool/Supply | Why You Need It & Pro Tips |

|---|---|

| Pedal Wrench (15mm) or Hex Wrench (6mm/8mm) | Check your pedals to see if they have wrench flats or a hex fitting on the axle's end. A dedicated pedal wrench with a long handle offers superior leverage compared to a standard spanner. |

| Bike-Specific Grease | This is non-negotiable. Applying a thin layer of grease to the new pedal threads prevents them from seizing inside the crank arm, making future removal much easier. |

| Clean Rags or Paper Towels | You'll need these for cleaning the crank arm threads and wiping away any excess grease or grime. |

| Penetrating Oil (Optional) | If your pedals are stuck fast, a quality penetrating oil can help break the bonds of corrosion. |

| eBike Essential: Sturdy Bike Stand | An e-bike's weight makes working on it precarious. A proper repair stand rated for e-bikes is the safest way to secure the bike, protecting both you and the bike from a fall. |

Preparing Your eBike for the Job

Once your tools are ready—whether that’s a 15mm wrench, a bike pedal torque wrench, or even a pedal plate removal tool—take a few minutes to prep your e-bike. A little setup makes removing bicycle pedals safer and smoother.

- Secure the bike: The best option is to clamp your e-bike into a sturdy repair stand, especially if you're dealing with bike crank and pedal systems that need extra leverage. No stand? Lay the bike gently on its non-drive side (the side without the chain). Use a soft surface like a blanket or cardboard to protect the frame and critical parts like the pedal body and bike pedal crank arm. Avoid propping the bike against a wall—it’s unstable and unsafe for pedal work.

- Move the chain onto the largest chainring in the front. This creates a buffer zone in case your hand slips during removal, sparing your knuckles from the sharp teeth near the bicycle pedal attachment. It’s a small but helpful trick when tackling stubborn pedals.

- Power down: As a safety rule when working on any part of an pedal assist bike, turn the power system completely off. If your battery comes off easily, remove it to reduce weight and make sure no power can be turned on by accident.

The eBike Difference

This isn't just a regular bike with a battery added on. The built-in nature of an e-bike's drive system means you have to be more careful during maintenance. Regular pedal removal guides often miss these important e-bike details that can prevent costly mistakes.

Mind the Motor and Housing

On most mid-drive e-bikes, the crank arms attach directly to or very near the motor unit. This area often has a plastic or thin metal cover that isn't made to handle impacts. When you're putting force on a wrench, a sudden slip can easily make the tool hit this case, causing cracks or damage. We've seen it happen in the workshop: a wrong move with a wrench or a sudden release of a stuck pedal can crack a motor's cover. Taking time to look at the area around the crank arm is a step pros never skip.

Watch for Wires and Sensors

The bottom bracket area on an e-bike has lots of electronic parts. You might find wiring for sensors that measure how fast you pedal, how hard you push, or your speed running along the frame or near the crankset. Before you start working or spraying any oil, do a quick visual check. Make sure no wires are in the path of your tool. Oil that's great for metal can damage wire insulation or hurt electronic sensors if you're not careful where you spray it.

Managing the Weight and Stability

We said it before, but it's worth saying again: an e-bike is heavy. The force needed to break a stuck pedal loose is big. If the bike isn't perfectly stable on a good stand, that force can easily knock over the whole bike. This can cause much more damage than just a stuck pedal, possibly hurting the gear shifter, handlebars, display screen, or the motor itself. Always make sure your bike is rock-solid before applying any real pressure.

Step-by-Step Removal Guide

The key thing to remember is that for both pedals, the wrench always turns toward the back of the bike to loosen. This simple trick gets rid of confusion about which way to turn.

| Pedal | Direction to Loosen (Unscrew) | Mnemonic |

|---|---|---|

| Right Pedal (Drive-Side) | Counter-Clockwise (Turn towards the rear of the bike) | Standard "Lefty-Loosey" |

| Left Pedal (Non-Drive-Side) | Clockwise (Turn towards the rear of the bike) | Reverse Thread! |

Removing the Right Pedal (Drive Side)

- Position the Crank: Turn the drive-side crank arm so it points forward, in the 3 o'clock position. This gives you the best angle to push down.

- Attach the Wrench: Put your 15mm pedal wrench onto the flats of the pedal axle. The handle of the wrench should angle up and toward the back. If using a hex key, put it firmly into the back of the axle.

- Apply Force: Hold the left crank arm steady with one hand to stop it from turning. With your other hand, push down firmly on the wrench. Your force should go toward the ground. According to guides on the proper technique for applying leverage, using your body weight works better and is safer than just using arm strength. The pedal should break free with a small pop.

- Unscrew by Hand: Once the first tension breaks, you should be able to spin the pedal the rest of the way out by hand.

Removing the Left Pedal (Non-Drive Side)

- Position the Crank: Move to the other side of the bike. Turn the non-drive-side crank arm so it also points forward, in the 9 o'clock position.

- Attach the Wrench: Put your wrench onto the pedal axle, again with the handle pointing up and toward the back.

- Apply Force: Hold the right crank arm steady and push down on the wrench. Remember, you are turning clockwise on this side, but the physical motion is the same: pushing down toward the ground when the crank is forward.

- Unscrew by Hand: Once loose, spin the pedal off. Notice the threads spiral in the opposite direction from the right pedal.

Troubleshooting Seized Pedals

Sometimes, a pedal just won't move. This usually happens when pedals were put in without grease, leading to rust between the steel pedal axle and the aluminum crank arm. Don't panic and don't grab a bigger hammer yet. Follow these steps that get stronger as you go.

Method 1: Improve Your Leverage

First, double-check how you're doing it. Make sure the crank arm is flat and you're pushing straight down with your body weight. If that's not enough, you can safely get more leverage. Some sources offer great tips for dealing with tight pedals. You can slide a "cheater bar," like a hollow metal pipe, over the end of your wrench to make it longer. Apply force smoothly and carefully; a sudden jerk can strip the wrench flats or make you lose balance.

Method 2: Penetrating Oil (The Right Way)

If leverage alone doesn't work, it's time for chemical help. Put a rag behind the crank arm to protect your e-bike's motor housing and any visible wiring. Apply a small, exact spray of penetrating oil right where the pedal axle threads into the crank arm. Let it sit for at least 15-30 minutes, or even longer for very stuck cases. This gives the oil time to get into the threads and break down the rust. After waiting, try again to loosen the pedal.

Method 3: The Percussive Method

Shock and vibration can often break a bond that steady pressure cannot. With the wrench securely in place, use a rubber or plastic hammer to give the end of the wrench a few sharp, firm taps in the loosening direction. Do not use a steel hammer, as it can damage your tool or the bike. Use controlled taps, not wild swings. This hitting force can often be the final trick that frees a stuck pedal.

When to Call a Professional

If you've tried all the above methods and the pedal is still stuck to the crank, it's time to stop. Putting on more force or heat (which we don't recommend for DIY on an e-bike because of the closeness of sensitive parts) risks permanently damaging the crank arm or even the motor. At this point, the smart move is to take your bike to a professional shop. They have special tools and experience, and as experts like Park Tool's professional-grade tool and technique recommendations show, sometimes you need a pro touch. The cost of their service is much less than replacing a damaged crankset or motor.

Installing Your New Pedals

Proper installation is just as important as proper removal. Doing it right makes sure your pedals are secure, quiet, and easy to remove next time.

- Identify Pedals: Your new pedals will be marked with an "L" and an "R". Do not mix them up, as the reverse-threaded left pedal will not fit into the right crank arm (and the other way around).

- Clean the Threads: Take a clean rag and completely wipe out the threads inside both crank arms. Remove any old grease, dirt, or metal pieces.

- Apply Grease: Put a thin, even layer of bike-specific grease on the threads of your new pedals. This is the single most important step for preventing them from getting stuck in the future.

- Start by Hand: Carefully thread each pedal into its correct crank arm by hand. The right pedal turns clockwise to tighten, and the left pedal turns counter-clockwise to tighten. You should be able to screw them in most of the way without a tool. If you feel resistance right away, stop. You may have the pedals swapped or are cross-threading them. Back it out and try again.

- Tighten with a Wrench: Once the pedal is hand-tight, use your pedal wrench or hex key to snug it down. The goal is to get it firm and secure.

- Torque to Spec (Optional but Recommended): For the most professional result, use a torque wrench to tighten the pedals to the manufacturer's specification, which is typically around 30-35 Newton-meters (Nm). This prevents over-tightening, which can damage the threads, and ensures they are tight enough not to work loose.

- Final Wipe: Use a rag to wipe away any excess grease that has squeezed out.

With your new pedals installed, you're ready to ride with confidence that the job was done correctly, safely, and with the special care your e-bike deserves.

Leave a comment